In Which Applications Are Brushless DC Motors Preferred Over Other Types of Electric Motors?

Brushless DC motors (BLDC motors) have become a pivotal technology in modern industry, offering significant advantages over traditional brushed DC motors and other types of electric motors. Characterized by their high efficiency, long lifespan, low maintenance, and precise control, BLDC motors are now widely adopted across multiple sectors. Understanding the applications where brushless DC motors excel provides insight into why they are increasingly favored in industries ranging from automotive and robotics to consumer electronics and industrial automation. This article explores the applications in which BLDC motors are preferred, explaining the technical reasons behind their growing adoption.

1. Understanding Brushless DC Motors

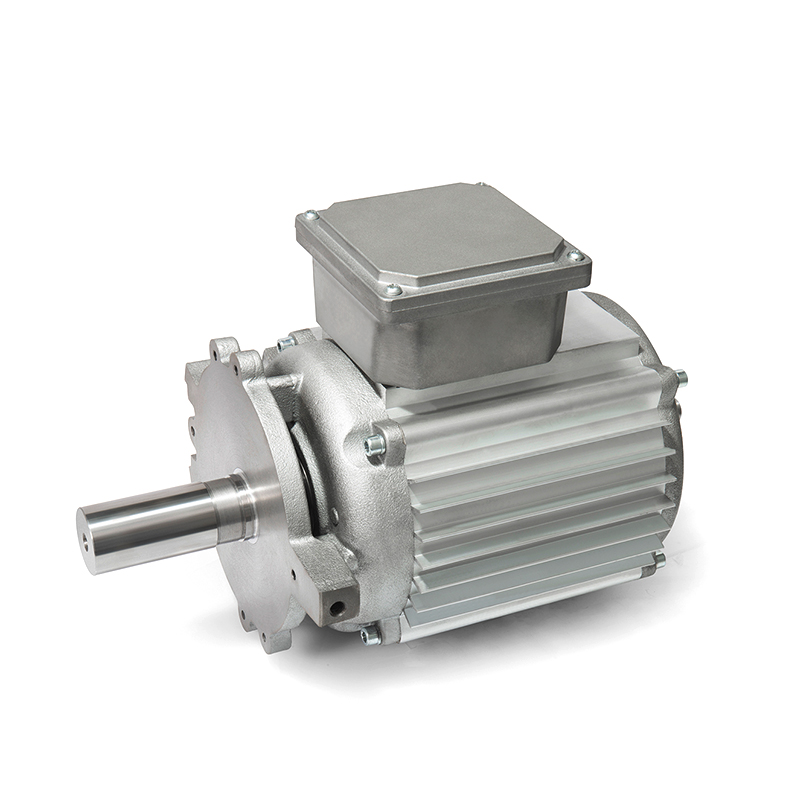

A brushless DC motor is an electric motor that operates without mechanical brushes, unlike conventional brushed DC motors. In a BLDC motor, electronic controllers replace brushes to switch the current in the windings, allowing the rotor to turn. This design results in less friction, reduced heat generation, and improved reliability.

Key advantages of BLDC motors include:

- High Efficiency: Reduced energy loss due to the absence of brushes.

- Long Lifespan: No brushes to wear out, decreasing maintenance needs.

- Precise Speed and Torque Control: Enabled by electronic controllers.

- Low Noise and Vibration: Smooth operation due to the lack of friction.

- Compact and Lightweight Designs: Ideal for space-constrained applications.

These characteristics make BLDC motors particularly suitable for applications where reliability, efficiency, and precise control are essential.

2. Electric Vehicles (EVs) and Hybrid Vehicles

One of the most prominent applications of BLDC motors is in electric vehicles (EVs) and hybrid vehicles (HEVs).

Why BLDC Motors Are Preferred:

- High Efficiency: BLDC motors convert a greater proportion of electrical energy into mechanical energy, improving battery life and vehicle range.

- Regenerative Braking Compatibility: BLDC motors efficiently handle regenerative braking, allowing energy recovery during deceleration.

- Compact Design: Enables integration into tight spaces such as wheel hubs or motor assemblies.

- Precise Torque Control: Provides smooth acceleration and deceleration, enhancing vehicle performance and safety.

Use Cases:

- Electric cars (Tesla, Nissan Leaf)

- Electric scooters and bikes

- Hybrid vehicles with integrated drive systems

In these applications, the long lifespan, energy efficiency, and precise control of BLDC motors make them superior to brushed DC motors or induction motors.

3. Robotics and Automation

Robotics and automation rely heavily on precision, speed control, and durability, making BLDC motors ideal.

Advantages in Robotics:

- Precise Motion Control: Electronic commutation allows fine-tuned speed and torque control, essential for robotic arms, CNC machines, and automated systems.

- High Torque-to-Weight Ratio: Provides sufficient power without adding excessive weight, critical for mobile robots or drones.

- Reduced Maintenance: No brushes to replace, minimizing downtime in industrial robots.

- Quiet Operation: Important for environments where noise must be limited.

Applications:

- Industrial robotic arms for assembly lines

- 3D printers and CNC machines

- Automated guided vehicles (AGVs)

- Surgical robots requiring precise movement

In these scenarios, BLDC motors outperform brushed motors and stepper motors due to efficiency, accuracy, and reliability.

4. Drones and Unmanned Aerial Vehicles (UAVs)

The drone industry has rapidly adopted BLDC motors for propulsion systems due to their exceptional power-to-weight ratio and reliability.

Benefits in Drone Applications:

- High Efficiency: Prolongs flight time by conserving battery power.

- Lightweight Design: Reduces total drone weight, enhancing maneuverability and endurance.

- High RPM Capability: Provides the rapid rotation required for propellers to generate lift.

- Durability: Withstands frequent takeoffs, landings, and high-speed rotation.

Use Cases:

- Consumer drones for photography and videography

- Industrial drones for surveying and inspection

- Military UAVs for reconnaissance

In these applications, BLDC motors are preferred over brushed motors because of their low maintenance, long operational life, and consistent high performance.

5. Consumer Electronics

BLDC motors are increasingly used in consumer electronics, where quiet operation, energy efficiency, and compact size are essential.

Applications in Consumer Electronics:

- Computer Cooling Fans: BLDC motors provide consistent airflow while operating quietly.

- Hard Disk Drives and Optical Drives: Precise rotational control is essential for reading and writing data.

- Electric Toothbrushes and Small Appliances: BLDC motors provide smooth and efficient operation with minimal wear.

- Air Conditioners and Refrigerators: Efficient and quiet operation reduces energy consumption and noise.

The efficiency, low noise, and long lifespan of BLDC motors make them superior to brushed motors in these compact and frequently used devices.

6. Industrial Equipment

In industrial settings, BLDC motors are used in applications requiring continuous operation, precision, and high efficiency.

Advantages for Industrial Use:

- Energy Savings: High efficiency reduces electricity costs in continuous operations.

- Reliability: No brushes mean less downtime due to maintenance or replacement.

- Precise Control: Allows exact speed and torque adjustments for machinery.

Applications:

- Conveyor systems and automated production lines

- Pumping systems and compressors

- CNC machines and milling equipment

- Fans and blowers in HVAC systems

BLDC motors are preferred in these industrial applications because their efficiency and longevity reduce operational costs and improve productivity.

7. Medical Devices

Medical devices often require quiet, precise, and reliable motors, making BLDC technology a perfect fit.

Applications in Medical Devices:

- Ventilators and Respirators: Provide reliable airflow control.

- Infusion Pumps: Precise control of medication delivery.

- Surgical Robots: Smooth and accurate motion control for delicate procedures.

- Mobility Equipment: Motorized wheelchairs and prosthetics benefit from efficient and compact BLDC motors.

The noise-free operation, precise control, and durability of BLDC motors are critical in medical environments, where reliability and patient safety are paramount.

8. Advantages of BLDC Motors Over Other Motor Types

BLDC motors are preferred in the applications mentioned above due to several inherent advantages:

| Feature | BLDC Motors | Brushed DC Motors | AC Induction Motors |

| Lifespan | Long (no brushes) | Shorter (brush wear) | Long, but less precise |

| Maintenance | Low | High (brush replacement) | Moderate |

| Efficiency | High | Moderate | Moderate |

| Noise | Low | High | Moderate |

| Control | Precise speed & torque | Limited | Less flexible |

| Size & Weight | Compact & lightweight | Heavier for same power | Bulky |

These advantages make BLDC motors suitable for high-performance, precision, and energy-conscious applications where other motors may not perform as effectively.

9. Future Trends

The adoption of BLDC motors continues to grow as technology advances:

- Integration with IoT: Smart motors with sensors and connectivity for predictive maintenance.

- Enhanced Energy Efficiency: New designs and materials reduce losses further, ideal for electric vehicles and renewable energy systems.

- Miniaturization: Smaller BLDC motors enable compact devices in consumer electronics and medical equipment.

- Automation and Robotics: Increased adoption in industrial automation and AI-driven machinery.

These trends suggest that BLDC motors will become even more ubiquitous across high-tech industries in the coming years.

10. Conclusion

Brushless DC motors are increasingly preferred over other types of electric motors in applications that demand high efficiency, precise control, durability, and low maintenance. Their versatility allows them to excel in electric vehicles, robotics, drones, consumer electronics, industrial equipment, and medical devices.

The combination of long lifespan, energy efficiency, quiet operation, and compact design positions BLDC motors as a superior choice for modern technology-driven applications. As industries continue to prioritize performance, sustainability, and reliability, brushless DC motors are expected to remain at the forefront of innovative motor solutions across multiple sectors.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体