The Power Behind the Clean: Understanding Car Wash AC Geared Motors

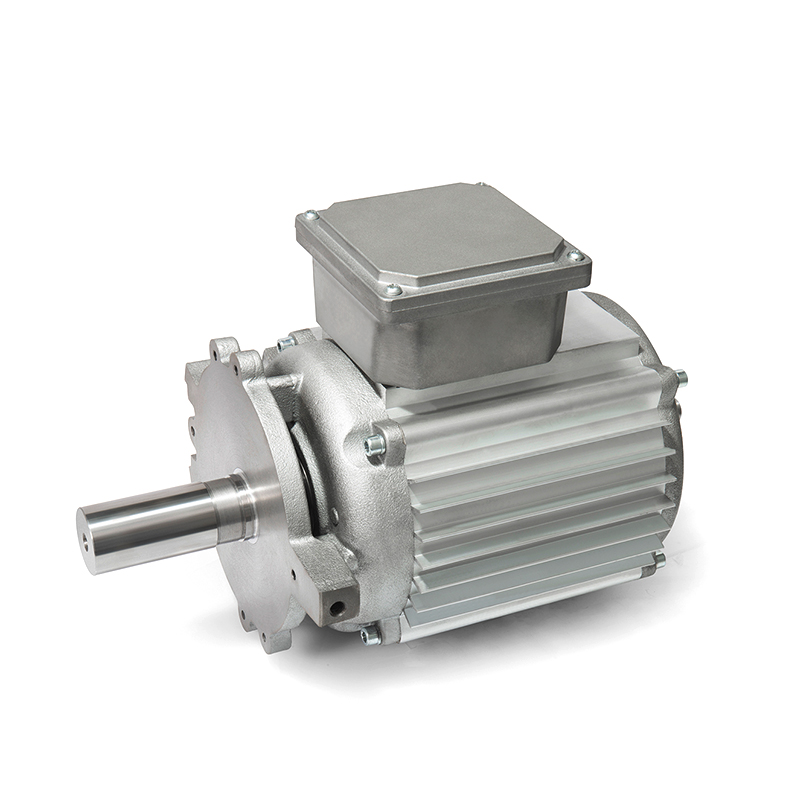

In the fast-paced world of automated car wash systems, performance, durability, and efficiency are key. One of the most critical components that make modern car washes possible is the AC geared motor . Specifically designed for high-torque, low-speed applications, the car wash AC geared motor plays a vital role in driving conveyor belts, rotating brushes, and other mechanical parts that ensure a smooth and effective cleaning process.

In a typical car wash setup, AC geared motors are responsible for:

Driving conveyor belts that move vehicles through the wash tunnel

Rotating high-pressure brushes and foam applicators

Operating lifting mechanisms for undercarriage cleaning nozzles

With their compact design and reliable output, AC geared motors are essential for ensuring consistent performance and safety in professional car wash operations.

An AC geared motor operates by converting electrical energy from the power supply into rotational mechanical energy. The AC motor provides the initial speed, while the gearbox reduces the output speed and multiplies the torque.

This allows the motor to handle heavy loads without drawing excessive power — making it ideal for use in continuous-duty environments like commercial car washes.

Key features include:

Variable Speed Control : Enables smooth acceleration and deceleration of moving parts

High Starting Torque : Ensures reliable operation even under full load

Low Maintenance Design : Sealed bearings and durable gears reduce wear and downtime

Thermal Protection : Built-in safeguards prevent overheating during long hours of operation

Why Use AC Geared Motors in Car Wash Systems?

Reliable Performance

Designed to withstand harsh conditions, including exposure to water, soap, and road grime.

Energy Efficiency

High-efficiency motors reduce electricity consumption and operating costs.

Precise Motion Control

Gearboxes allow for accurate positioning and speed regulation of mechanical components.

Longevity

Robust construction ensures long service life, even in demanding 24/7 operations.

Easy Integration

Can be paired with PLC control systems for automation and remote monitoring.

Common Applications in Car Wash Equipment

Tunnel wash conveyors

Rotating tire brushes and side brushes

Drying fans and lifters

Entry/exit gate operators

Turntable systems in self-service bays

These motors are often available in different power ratings (e.g., 0.5kW to 5.5kW) and gear ratios to suit various system designs and operational needs.

Behind every efficient and high-quality car wash lies a powerful yet precise heart — the AC geared motor . As demand for automated car wash solutions continues to grow, so does the need for durable, efficient, and reliable motor technology.

Whether you're designing a new car wash system or maintaining an existing one, choosing the right car wash AC geared motor can significantly enhance performance, reduce maintenance issues, and improve overall customer satisfaction.

Investing in quality geared motor technology is not just about keeping things moving — it's about ensuring your car wash business runs smoothly, efficiently, and profitably.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体