Can Cleaner Motors Power the Future of Efficient Cleaning?

In an era where sustainability, energy efficiency, and performance are top priorities, the humble cleaning motor has emerged as a critical component in the evolution of cleaning technology. From robotic vacuums to industrial scrubbers, the motor is the beating heart of any cleaning device—determining suction power, energy consumption, noise levels, and overall effectiveness. But what makes a "cleaner motor" truly efficient? And how do advancements in motor technology contribute to smarter, greener, and more powerful cleaning solutions? Let’s explore the key components that drive efficient cleaning and examine whether modern motor innovations are paving the way for a cleaner, more sustainable future.

What Is a Cleaner Motor?

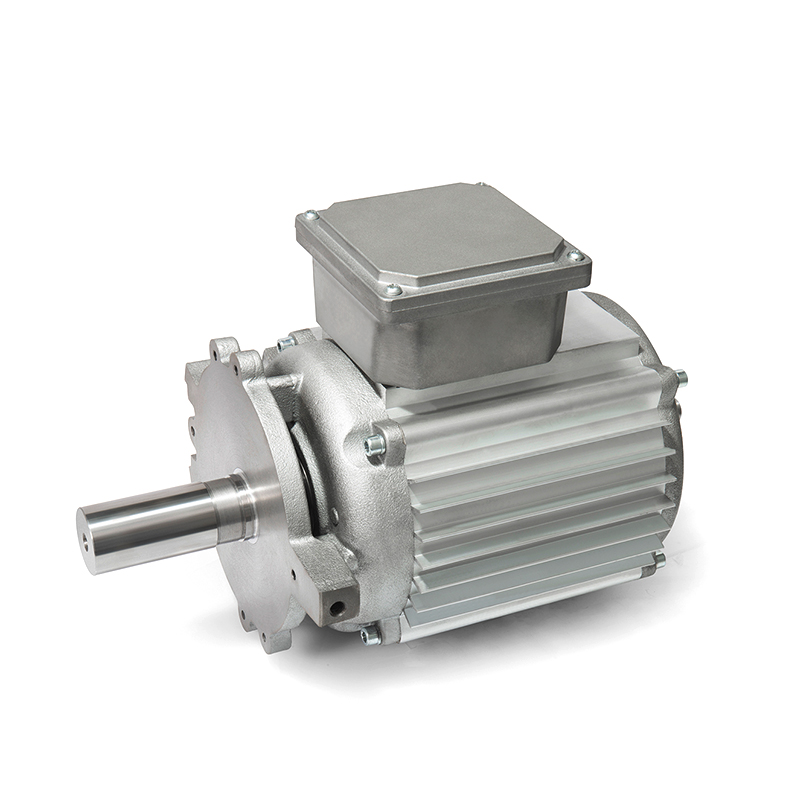

A cleaner motor refers to the electric motor used in cleaning appliances such as vacuum cleaners, floor scrubbers, pressure washers, air purifiers, and robotic cleaning devices. Unlike standard motors, cleaner motors are engineered for high performance in compact designs, with an emphasis on durability, energy efficiency, and quiet operation.

These motors generate the suction, airflow, or mechanical motion required to remove dust, debris, and contaminants from surfaces. As consumer demand grows for quieter, longer-lasting, and eco-friendly appliances, manufacturers are investing heavily in advanced motor technologies to meet these expectations.

Key Components of Efficient Cleaner Motors

The efficiency and reliability of a cleaner motor depend on several critical components. Understanding these elements helps explain how modern motors outperform their predecessors.

1. Brushless DC (BLDC) Motors

One of the most significant advancements in cleaner motor technology is the shift from brushed to brushless DC motors. BLDC motors eliminate the carbon brushes used in traditional motors, reducing friction, heat, and wear. This results in:

Higher energy efficiency (up to 30% more efficient than brushed motors)

Longer lifespan

Quieter operation

Better speed control

Many high-end vacuum cleaners, such as those from Dyson and Samsung, now use BLDC motors to deliver powerful suction with minimal energy loss.

2. Impeller and Fan Design

The impeller (or fan) is responsible for creating airflow and suction. Advanced aerodynamic designs—often inspired by jet engines or turbine blades—maximize air movement while minimizing turbulence and noise. Precision-engineered blades made from lightweight, durable materials like polycarbonate enhance performance and reduce energy consumption.

3. Electronic Speed Controllers (ESC)

Modern cleaner motors use electronic controllers to regulate motor speed based on cleaning conditions. For example, robotic vacuums can detect carpet vs. hardwood and automatically adjust suction power. This intelligent control reduces unnecessary energy use and extends battery life.

4. Thermal Protection Systems

Overheating is a common cause of motor failure. Efficient cleaner motors include thermal sensors and protection circuits that shut down the motor if temperatures rise too high, preventing damage and improving safety.

5. High-Grade Bearings and Sealed Housings

Dust and debris can quickly degrade motor performance. Sealed motor housings and high-quality bearings protect internal components, ensuring smooth operation even in dirty environments. This is especially important in industrial cleaning equipment.

6. Lightweight and Compact Design

Efficiency isn’t just about power—it’s also about form. Modern cleaner motors are designed to be smaller and lighter without sacrificing performance. This allows for sleeker, more maneuverable cleaning devices, particularly in handheld and robotic models.

Why Motor Efficiency Matters

The importance of efficient cleaner motors extends beyond just better cleaning. Here’s why they matter:

Energy Savings: Efficient motors consume less electricity, reducing both operating costs and environmental impact.

Battery Life: In cordless devices, motor efficiency directly affects battery longevity. A more efficient motor means longer cleaning sessions between charges.

Noise Reduction: Quieter motors improve user experience, making cleaning less disruptive in homes, offices, and public spaces.

Sustainability: Longer-lasting motors reduce electronic waste and the need for frequent replacements.

Applications Across Industries

Efficient cleaner motors are transforming cleaning in various sectors:

Residential: Smart vacuums and cordless stick vacuums use BLDC motors for powerful, quiet cleaning.

Commercial: Office and hotel cleaning equipment benefit from durable, energy-efficient motors that reduce maintenance costs.

Industrial: High-powered scrubbers and sweepers rely on robust motors to handle large-scale cleaning with minimal downtime.

Healthcare: Hospitals use ultra-efficient, low-noise motors in air purifiers and vacuum systems to maintain sterile environments.

Challenges and Considerations

Despite their advantages, advanced cleaner motors come with challenges:

Higher Initial Cost: BLDC and smart motors are more expensive to produce, which can increase the retail price of cleaning devices.

Complex Repairs: The integration of electronics makes repairs more difficult and often requires specialized technicians.

Material Sourcing: Rare earth metals used in some high-performance motors raise concerns about sustainability and supply chain ethics.

Cleaner Motors Compared: A Performance Overview

The table below compares different types of motors commonly used in cleaning devices:

| Motor Type | Efficiency | Lifespan | Noise Level | Energy Use | Best For |

| Brushed DC Motor | Low-Medium | 300–500 hrs | High | High | Budget vacuums, basic tools |

| Brushless DC (BLDC) | High | 2,000+ hrs | Low | Low | Premium vacuums, robotics |

| Universal Motor | Medium | 500–1,000 hrs | High | Medium-High | Corded vacuums, older models |

| Coreless Motor | Medium-High | 1,000 hrs | Low | Low | Small devices, handheld cleaners |

| Stepper Motor (for robotics) | Medium | Varies | Very Low | Very Low | Navigation, precision movement |

As shown, BLDC motors lead in efficiency, lifespan, and noise reduction—making them the gold standard for modern cleaning technology.

The Future of Cleaner Motors

The future of cleaning is smart, sustainable, and powered by innovation. Emerging trends include:

AI-Integrated Motors: Motors that learn user habits and optimize performance in real time.

Regenerative Braking: In robotic cleaners, energy from deceleration could be stored and reused.

Eco-Materials: Development of motors using recyclable or bio-based components.

Wireless Power Transmission: Eliminating batteries altogether with inductive charging systems.

As global energy standards tighten and consumers demand greener products, cleaner motors will play a pivotal role in shaping the next generation of cleaning appliances.

Final Thoughts: Are Cleaner Motors the Key to Efficient Cleaning?

The answer is a resounding yes. The motor is no longer just a mechanical component—it’s an intelligent, energy-conscious engine driving the future of cleanliness. From homes to hospitals, efficient cleaner motors are enabling faster, quieter, and more sustainable cleaning solutions.

While challenges remain in cost and recyclability, ongoing innovation continues to push the boundaries of what’s possible. As technology evolves, cleaner motors won’t just improve how we clean—they’ll redefine what it means to clean efficiently in the 21st century.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体