What Makes AC Geared Motors Ideal for Industrial Applications?

In the world of industrial machinery and automation, the AC geared motor stands out as a vital component that combines the power of an alternating current (AC) motor with a gearbox to deliver controlled torque and speed. Whether it's conveyor systems, packaging equipment, or machine tools, AC geared motors provide the efficiency and reliability essential for smooth operations. But what exactly are AC geared motors? How do they work, and why are they preferred in many industrial setups?

What is an AC Geared Motor?

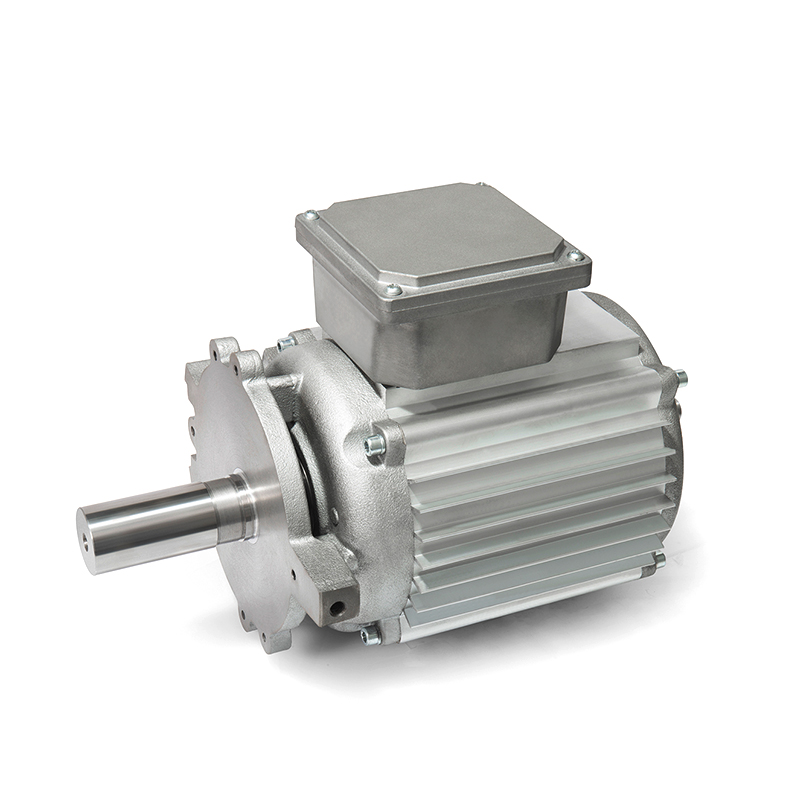

An AC geared motor is a type of electric motor powered by alternating current (AC) that incorporates a gearbox to reduce speed and increase torque. The gearbox, typically a set of gears arranged in a compact housing, allows the motor’s highspeed, lowtorque output shaft to be converted into a lowspeed, hightorque shaft suited for various mechanical tasks.

The integration of the motor and gearbox into a single unit offers benefits such as compact design, simplified installation, and improved performance.

Components of an AC Geared Motor

1. AC Motor: The core driving component powered by AC electricity, available in different designs such as induction motors or synchronous motors.

2. Gearbox (Gear Reducer): Contains gears (spur, helical, worm, or planetary) that reduce the motor’s output speed while increasing torque.

3. Output Shaft: Delivers the adjusted speed and torque to the connected machinery.

4. Housing: Encloses the motor and gearbox, providing protection and structural integrity.

How Does an AC Geared Motor Work?

The motor receives AC power and converts electrical energy into mechanical rotational energy. This rotation is then transmitted through the gearbox, which adjusts the speed and torque according to the gear ratio.

Gear Reduction: By using larger gears connected to smaller gears or worm gears, the output speed decreases proportionally while torque increases.

Output: The output shaft spins at the reduced speed with increased force, suitable for driving heavy loads or precise movements.

Types of AC Geared Motors

1. Helical Gear Motor

Uses helical gears which have angled teeth for smoother and quieter operation.

High efficiency and suitable for heavyduty applications.

2. Worm Gear Motor

Utilizes worm and worm wheel gears that provide high reduction ratios and torque in a compact design.

Known for selflocking features, preventing reverse motion.

3. Spur Gear Motor

Employs straightcut gears, simple design, costeffective.

Best for moderate speed and load applications.

4. Planetary Gear Motor

Features gears arranged in a planetary configuration, offering high torque density and compactness.

Used in applications requiring precise motion control.

Advantages of AC Geared Motors

High Torque Output: Gearboxes allow motors to deliver significantly higher torque than standalone motors.

Speed Control: Gear ratios enable tailored speed outputs for different applications.

Compact Design: Integrated motor and gearbox reduce space and simplify mounting.

Energy Efficiency: Proper gear selection minimizes energy losses during operation.

Low Maintenance: Durable gear designs ensure long service life with minimal upkeep.

CostEffectiveness: Combining motor and gearbox reduces overall equipment costs.

Reliability: Robust construction suitable for harsh industrial environments.

Applications of AC Geared Motors

AC geared motors are widely used across industries due to their versatility:

Conveyor Systems: For consistent speed and torque to move materials efficiently.

Packaging Machinery: Precision motion and control in wrapping, filling, and labeling.

Automated Gates and Doors: Smooth and reliable operation for opening and closing mechanisms.

Food Processing Equipment: Durable motors that withstand moisture and heavy use.

Textile Machines: Providing accurate speeds and torque for fabric processing.

Robotics and Automation: Essential for precise positioning and load handling.

HVAC Systems: Driving fans and blowers with controlled speed.

How to Select the Right AC Geared Motor?

When choosing an AC geared motor, consider:

Load Requirements: Calculate the torque and speed needed to drive your application.

Gear Type: Choose based on noise level, efficiency, and size constraints.

Power Supply: Ensure compatibility with your facility’s voltage and frequency.

Mounting Configuration: Footmounted, flangemounted, or shaftmounted depending on installation.

Environmental Conditions: Look for protection ratings (IP ratings) against dust, water, and chemicals.

Control Options: Whether you need variable speed drives or fixedspeed motors.

Maintenance Tips for AC Geared Motors

Regular Lubrication: Keep gears properly lubricated to reduce wear and overheating.

Inspect for Wear: Monitor gears and bearings for signs of damage or noise.

Clean Environment: Avoid dust and debris accumulation inside the motor and gearbox.

Check Electrical Connections: Ensure secure wiring to prevent motor failure.

Temperature Monitoring: Prevent overheating by maintaining proper ventilation.

Common Challenges and Solutions

Overheating: Use motors with adequate cooling systems and avoid overloads.

Gear Wear: Select highquality gears and maintain lubrication schedules.

Noise: Choose helical or planetary gear motors for quieter operation.

Vibration: Properly mount and balance motors to reduce vibration.

Future Trends in AC Geared Motors

Smart Motors: Integration with IoT sensors for predictive maintenance and performance monitoring.

Energy Efficiency: Development of motors with higher efficiency ratings and reduced losses.

Compact Designs: Continued miniaturization for spaceconstrained applications.

Advanced Materials: Use of stronger, lighter materials for gearboxes and housings.

Conclusion

AC geared motors are indispensable in modern industrial applications, offering controlled speed and high torque in a compact and efficient package. Their versatility, durability, and adaptability to various loads and environments make them ideal for a wide range of machinery and equipment.

Understanding the types, working principles, advantages, and selection criteria of AC geared motors enables engineers and buyers to make informed decisions that optimize performance and reduce downtime.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体