Author: Admin Date: 2024-03-27

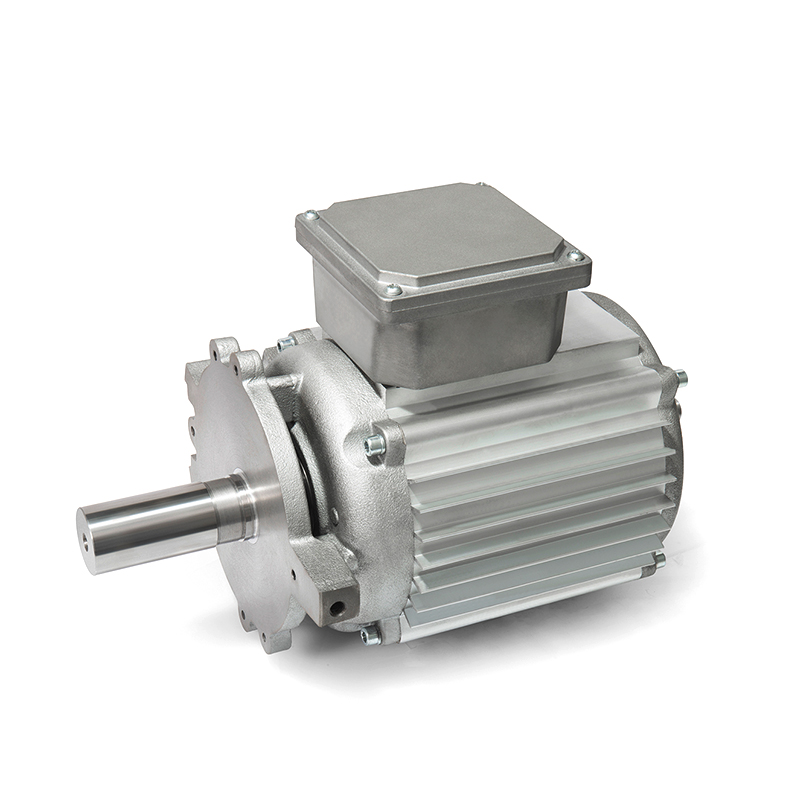

How do you maintain and lubricate single-phase induction motors for optimal performance and longevity?

Maintaining and lubricating single-phase induction motors is essential for ensuring optimal performance and longevity. Here are the steps typically involved in this process:

Perform routine visual inspections of the motor to check for any signs of wear, damage, or overheating. Look for loose connections, damaged insulation, or excessive vibration.

Keep the motor and its surrounding area clean to prevent the accumulation of dirt, dust, or debris. Use compressed air or a soft brush to clean the exterior and ventilation openings of the motor.

Many single-phase induction motors have oil-lubricated bearings that require periodic lubrication to reduce friction and wear. Refer to the motor manufacturer's specifications for the type of lubricant and lubrication interval recommended for your motor.

If your motor has oil-lubricated bearings, regularly check the oil level using the oil level sight glass or dipstick. Ensure that the oil level is within the recommended range and top up if necessary.

Periodically, as per the manufacturer's recommendations, change the oil in the motor bearings. Over time, oil can degrade and become contaminated, leading to reduced lubricating properties.

If bearings show signs of wear, such as increased noise or vibration, or if lubrication does not resolve the issue, consider replacing the bearings. Follow proper procedures for bearing replacement to ensure correct installation and alignment.

Monitor the temperature of the motor during operation using a temperature monitoring device or infrared thermometer. Excessive heat can indicate problems such as overloading or insufficient cooling.

Consider the operating environment of the motor. If the motor is exposed to extreme temperatures, humidity, or corrosive substances, take appropriate measures to protect it, such as using enclosures or selecting suitable sealing options.

If the motor experiences vibration or imbalance issues, consider dynamic balancing to ensure smooth operation and reduce stress on components.

For complex maintenance tasks or if you're unsure about any aspect of motor maintenance, consult with qualified technicians or motor specialists for professional assistance.

By following these maintenance practices, you can help ensure that your single-phase induction motor operates efficiently and reliably, contributing to its longevity and minimizing the risk of unexpected failures.

Perform routine visual inspections of the motor to check for any signs of wear, damage, or overheating. Look for loose connections, damaged insulation, or excessive vibration.

Keep the motor and its surrounding area clean to prevent the accumulation of dirt, dust, or debris. Use compressed air or a soft brush to clean the exterior and ventilation openings of the motor.

Many single-phase induction motors have oil-lubricated bearings that require periodic lubrication to reduce friction and wear. Refer to the motor manufacturer's specifications for the type of lubricant and lubrication interval recommended for your motor.

If your motor has oil-lubricated bearings, regularly check the oil level using the oil level sight glass or dipstick. Ensure that the oil level is within the recommended range and top up if necessary.

Periodically, as per the manufacturer's recommendations, change the oil in the motor bearings. Over time, oil can degrade and become contaminated, leading to reduced lubricating properties.

If bearings show signs of wear, such as increased noise or vibration, or if lubrication does not resolve the issue, consider replacing the bearings. Follow proper procedures for bearing replacement to ensure correct installation and alignment.

Monitor the temperature of the motor during operation using a temperature monitoring device or infrared thermometer. Excessive heat can indicate problems such as overloading or insufficient cooling.

Consider the operating environment of the motor. If the motor is exposed to extreme temperatures, humidity, or corrosive substances, take appropriate measures to protect it, such as using enclosures or selecting suitable sealing options.

If the motor experiences vibration or imbalance issues, consider dynamic balancing to ensure smooth operation and reduce stress on components.

For complex maintenance tasks or if you're unsure about any aspect of motor maintenance, consult with qualified technicians or motor specialists for professional assistance.

By following these maintenance practices, you can help ensure that your single-phase induction motor operates efficiently and reliably, contributing to its longevity and minimizing the risk of unexpected failures.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体