How Does an Electric Motor Transaxle Differ from a Traditional Transmission?

The automotive industry is undergoing a profound transformation, driven by the global shift toward electrification. Among the critical components in electric vehicles (EVs) and hybrid vehicles is the electric motor transaxle, a system that combines the functions of an electric motor, transmission, and differential into a single compact unit. Understanding how electric motor transaxles differ from traditional internal combustion engine (ICE) transmissions is essential for engineers, automotive enthusiasts, and consumers who want to grasp the technological changes shaping modern vehicles.

This article provides a comprehensive analysis of the differences between electric motor transaxles and traditional transmissions, focusing on design, performance, efficiency, maintenance, and overall vehicle dynamics.

1. Overview of Traditional Transmissions

Traditional transmissions are integral components of internal combustion engine vehicles. They serve the primary purpose of transmitting engine power to the wheels while adjusting torque and speed according to driving conditions.

1.1 Types of Traditional Transmissions

- Manual Transmission (MT): Drivers manually engage and disengage gears using a clutch pedal and gear lever.

- Automatic Transmission (AT): Uses a hydraulic torque converter and planetary gear sets to automatically select gears.

- Continuously Variable Transmission (CVT): Employs a pulley and belt system to provide an infinite range of gear ratios.

- Dual-Clutch Transmission (DCT): Uses two clutches to enable faster gear changes and improved efficiency.

1.2 Functions of Traditional Transmissions

- Adjust engine torque to meet different driving conditions (e.g., acceleration, hill climbing).

- Maintain engine operation within an efficient RPM range.

- Enable smooth power delivery to the drive wheels.

Traditional transmissions are complex mechanical systems, often containing dozens of gears, shafts, clutches, and hydraulic systems, which contribute to weight, size, and maintenance requirements.

2. Overview of Electric Motor Transaxles

An electric motor transaxle integrates three critical components into a single unit:

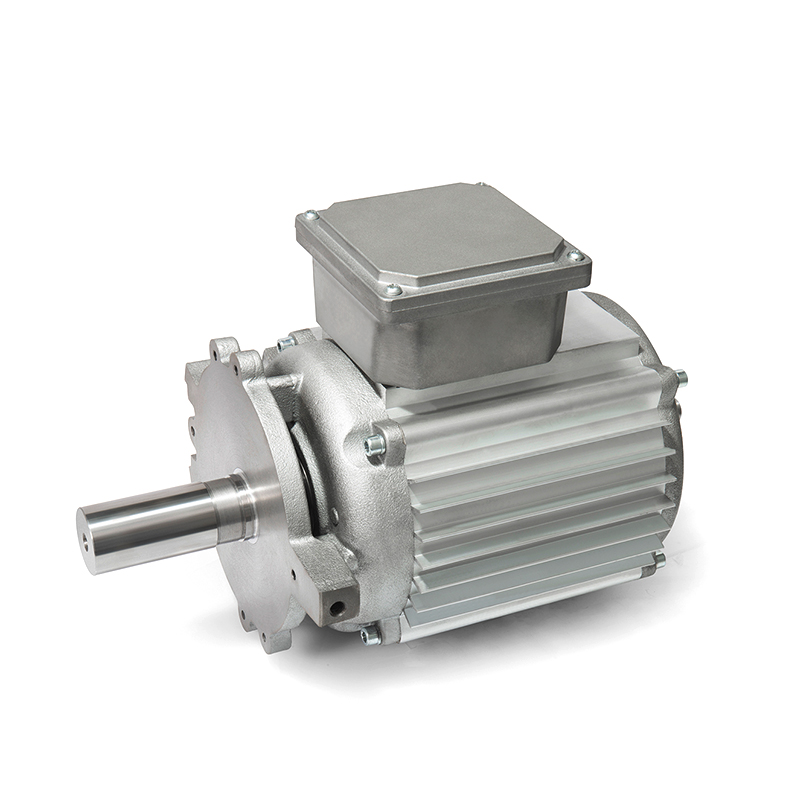

- Electric Motor: Converts electrical energy from the battery into mechanical torque.

- Transmission/Reduction Gear: Adjusts torque and speed to match wheel requirements.

- Differential: Distributes torque between the drive wheels while allowing them to rotate at different speeds during turns.

This integration is particularly common in front-wheel-drive or rear-wheel-drive EVs, where the transaxle is mounted directly on the driven axle.

2.1 Key Features of Electric Motor Transaxles

- Single-Speed or Two-Speed Gear Ratios: Unlike traditional transmissions, most electric motor transaxles operate with a single reduction ratio because electric motors can provide high torque over a wide speed range.

- Compact Design: Combining motor, transmission, and differential reduces overall component count and saves space.

- Efficient Power Delivery: Fewer mechanical losses compared to multi-speed ICE transmissions.

3. Core Differences Between Electric Motor Transaxles and Traditional Transmissions

3.1 Complexity and Component Count

- Traditional Transmission: Contains multiple gears, clutches, hydraulic systems, and shift mechanisms. Complexity is necessary to keep the engine in its optimal RPM range.

- Electric Motor Transaxle: Requires fewer components due to the electric motor’s ability to deliver consistent torque across a broad speed range. Often, a single reduction gear is sufficient, reducing mechanical complexity and potential failure points.

Implication: Reduced complexity in EVs leads to lower maintenance needs and higher reliability.

3.2 Gear Ratios and Torque Delivery

- Traditional Transmission: Uses multiple gears to convert high-RPM, low-torque output of an ICE into usable torque for wheels. Gear shifting is necessary to maintain efficiency and performance.

- Electric Motor Transaxle: Electric motors produce instantaneous torque at low RPMs and maintain effective power across a wide speed range, reducing or eliminating the need for multiple gears.

Implication: Drivers experience smooth, continuous acceleration without the need for traditional gear shifts, resulting in a simpler driving experience.

3.3 Efficiency

- Traditional Transmission: Mechanical complexity, friction, and hydraulic losses in multi-speed systems reduce overall drivetrain efficiency. Efficiency typically ranges from 80-90% depending on transmission type and driving conditions.

- Electric Motor Transaxle: With fewer moving parts and direct power delivery, transaxles often achieve higher efficiency, frequently exceeding 90% in energy conversion from battery to wheels.

Implication: Higher efficiency contributes to longer EV range and lower energy consumption.

3.4 Maintenance Requirements

- Traditional Transmission: Requires periodic fluid changes, clutch replacements (in manual or DCT systems), and potential repairs of hydraulic or mechanical components.

- Electric Motor Transaxle: Maintenance is minimal, primarily focusing on lubrication of the reduction gears and occasional inspection of the motor and differential. No clutch replacement is needed in single-speed designs.

Implication: EV owners benefit from lower maintenance costs and reduced downtime.

3.5 Size and Weight

- Traditional Transmission: Large, heavy, and complex, adding to overall vehicle weight and requiring additional space in the engine bay.

- Electric Motor Transaxle: Compact, lightweight, and often mounted directly on the axle, freeing up space for batteries or cargo and reducing vehicle weight.

Implication: Weight reduction and space efficiency improve vehicle handling, performance, and design flexibility.

3.6 Driving Experience

- Traditional Transmission: Gear shifts can introduce interruptions in acceleration and require driver skill (in manual transmissions) or adaptation to automatic systems.

- Electric Motor Transaxle: Smooth and seamless acceleration due to the electric motor’s continuous torque curve. Regenerative braking can also be integrated for energy recovery, enhancing efficiency and driving comfort.

Implication: EVs with transaxles offer a quiet, responsive, and effortless driving experience.

4. Design Considerations

When designing electric motor transaxles, engineers focus on:

- Gear Reduction Ratio: Ensures optimal balance between acceleration and top speed.

- Motor Power and Torque: Must match vehicle weight and performance requirements.

- Thermal Management: Electric motors generate heat; efficient cooling is essential to maintain performance and longevity.

- Differential Type: Limited-slip or open differentials may be used to optimize traction and stability.

In contrast, traditional transmissions require extensive engineering to accommodate multi-speed gear sets, torque converters, or clutch systems.

5. Emerging Trends and Innovations

- Two-Speed Electric Transaxles: Some high-performance EVs are now using two-speed reductions to optimize acceleration and efficiency at higher speeds.

- Integration with Vehicle Control Systems: Advanced transaxles work seamlessly with regenerative braking, traction control, and stability systems.

- Lightweight Materials: Use of aluminum and composite materials reduces weight further, improving vehicle range and handling.

- Additive Manufacturing: Components like gear sets and housings can be optimized for weight and performance using 3D printing.

These innovations continue to differentiate electric motor transaxles from traditional transmission systems in terms of efficiency, reliability, and adaptability.

6. Advantages of Electric Motor Transaxles Over Traditional Transmissions

- Fewer Moving Parts: Reduces mechanical losses, maintenance, and failure points.

- Higher Efficiency: Direct torque delivery and single reduction gear improve energy use.

- Compact and Lightweight: Frees up space for battery packs or cabin design improvements.

- Simplified Driving Experience: Smooth, gearless acceleration enhances comfort.

- Lower Maintenance Costs: Minimal service requirements compared to ICE transmissions.

- Integration with Regenerative Braking: Enhances overall EV efficiency.

7. Limitations of Electric Motor Transaxles

While electric motor transaxles offer many advantages, there are some limitations:

- High Initial Cost: Advanced materials and integrated designs can be expensive.

- Thermal Management Requirements: High torque and sustained power generation require careful cooling solutions.

- Limited Top Speed Optimization: Single-speed transaxles may compromise efficiency or performance at very high speeds, though this is addressed by some dual-speed designs.

- Specialized Repair: Repairs or replacements require specialized knowledge and may not be as widely serviceable as traditional transmissions.

8. Conclusion

Electric motor transaxles represent a fundamental shift in automotive drivetrain technology. Unlike traditional transmissions, which rely on multiple gears, clutches, and hydraulic systems to optimize the internal combustion engine, electric motor transaxles leverage the instantaneous torque and broad efficiency range of electric motors. This allows for simplified design, higher efficiency, reduced maintenance, and smoother driving performance.

Key differences include:

- Reduced mechanical complexity and fewer components.

- Seamless torque delivery with little or no gear shifting.

- Higher energy efficiency and integration with regenerative braking.

- Compact and lightweight design, enabling better vehicle packaging.

While electric motor transaxles are not without challenges, including cost and thermal management, they are central to the advantages of EVs over conventional ICE vehicles. As automotive technology continues to evolve, electric motor transaxles will remain a critical element in enhancing performance, reliability, and overall vehicle efficiency, driving the future of sustainable transportation.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体