What Are the Common Causes of Failure in Three-Phase Induction Motors?

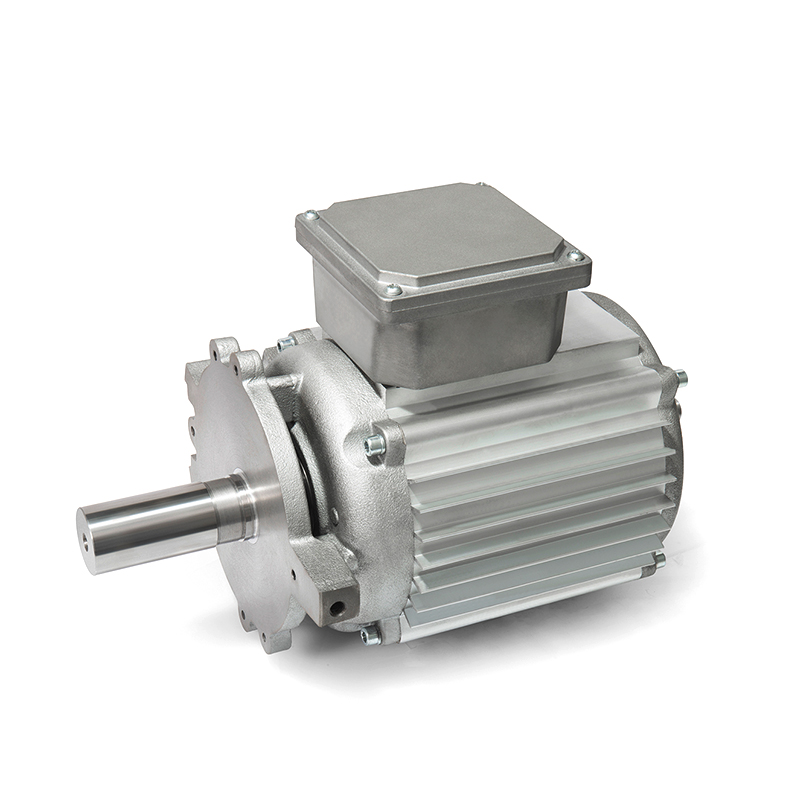

Three-phase induction motors are the backbone of modern industry, used in a wide range of applications, from pumps and compressors to conveyor belts and fans. Despite their reliability and robustness, these motors can experience failures due to various factors. Understanding the common causes of failure can help in troubleshooting, preventive maintenance, and improving motor longevity. In this article, we will explore the primary reasons for the failure of three-phase induction motors and provide insights into how to address these issues.

1. Overheating

One of the most common causes of failure in three-phase induction motors is overheating. The motor’s windings are designed to handle specific temperatures, and when these limits are exceeded, it can lead to insulation breakdown, reduced motor life, or complete failure.

Causes of Overheating:

-

Overload: If the motor is running at or beyond its rated load for extended periods, it can overheat. Motors running under overload conditions cause the current to exceed the design parameters, leading to excessive heat generation.

-

Ambient Temperature: Motors operating in environments with high ambient temperatures are more prone to overheating, especially if they lack adequate ventilation or cooling systems.

-

Insufficient Cooling or Ventilation: Motors rely on proper airflow or external cooling methods to dissipate heat. If ventilation systems are blocked, fans fail, or the motor is enclosed in an unsuitable housing, the motor may overheat.

-

Improper Voltage: Low or fluctuating supply voltage can cause the motor to work inefficiently, generating excess heat. Similarly, excessive voltage can lead to insulation breakdown due to overstress.

Prevention and Solutions:

- Ensure that the motor is not overloaded by accurately sizing it according to the application.

- Regularly inspect and maintain ventilation and cooling systems.

- Use temperature monitoring devices like thermocouples to track motor health.

- Operate the motor within the recommended voltage range.

2. Electrical Imbalance

A common issue in three-phase induction motors is electrical imbalance in the supply voltage. When the voltages in the three phases are not equal, it creates an imbalance, which can cause a variety of motor problems.

Causes of Electrical Imbalance:

-

Uneven Power Supply: If one or two of the phases deliver significantly higher or lower voltage than the others, it creates a situation of unbalanced voltage. This may result from faulty transformers, supply line issues, or improper wiring.

-

Harmonics: Distorted waveforms due to non-linear loads can also lead to voltage imbalances. This is often seen in systems with large electronic loads, such as variable frequency drives (VFDs).

Consequences:

- Increased motor heating and vibration.

- Reduced efficiency and performance.

- Shortened motor life due to excessive currents in windings.

Prevention and Solutions:

- Regularly monitor phase voltages to ensure balanced electrical supply.

- Install phase sequence indicators to detect imbalances early.

- Consider installing harmonic filters or devices that mitigate voltage distortion in systems prone to harmonic interference.

3. Bearing Failures

Bearings support the rotor’s rotation within the stator, and any issues with them can lead to serious motor failure. Bearing failure is one of the most common mechanical failures in motors.

Causes of Bearing Failures:

-

Lubrication Issues: Insufficient lubrication or improper lubrication leads to increased friction, which accelerates wear and tear on the bearings.

-

Contamination: Dirt, dust, or moisture entering the bearing housing can cause abrasive damage, leading to bearing wear and motor malfunction.

-

Misalignment: If the motor shaft and bearings are misaligned, it can cause uneven wear and vibration, eventually leading to bearing failure.

-

Excessive Load: Overloading the motor can increase the stress on bearings, causing them to fail prematurely.

Prevention and Solutions:

- Regularly check and replace lubricants, ensuring they meet the motor’s specifications.

- Protect the motor from dust, moisture, and contamination by sealing the motor properly.

- Ensure proper alignment during installation and maintenance.

- Use high-quality bearings and ensure the motor operates within its rated load.

4. Electrical Faults

Electrical faults such as short circuits, open circuits, or ground faults can damage the motor windings, leading to performance degradation or total failure.

Causes of Electrical Faults:

-

Insulation Breakdown: The insulation between the windings deteriorates over time due to exposure to heat, moisture, and mechanical stress, which can lead to short circuits.

-

Electrical Surge: A sudden surge in electrical current, possibly from power spikes or switching operations, can damage the motor windings and cause a short circuit.

-

Ground Faults: A ground fault occurs when there is an unintended connection between the motor windings and the ground, leading to improper current flow and overheating.

Prevention and Solutions:

- Regularly inspect motor insulation for signs of wear and tear.

- Use surge protectors and fuses to prevent electrical surges from damaging the motor.

- Install ground fault detection systems to identify and eliminate ground issues early.

5. Vibration and Mechanical Stress

Excessive vibration and mechanical stress can result in motor damage and failure, especially if the motor is operating under improper conditions.

Causes of Vibration:

-

Imbalance in the Rotor: A rotor that is out of balance, due to manufacturing defects or wear and tear, can cause excessive vibrations during operation.

-

Misalignment: As mentioned earlier, misalignment between the motor shaft and coupling can cause vibration and uneven wear on the motor’s components.

-

Unstable Foundations: If the motor is mounted on an unstable or improperly aligned base, it can lead to vibrations, which cause wear on bearings and other parts.

Consequences:

- Increased bearing wear.

- Distorted rotor shape and possible winding damage.

- Premature motor failure.

Prevention and Solutions:

- Perform regular vibration analysis to detect early signs of imbalance.

- Ensure proper alignment and mounting of the motor and its components.

- Balance the rotor if necessary, especially after repairs or replacements.

6. Overvoltage and Undervoltage

Operating the motor under conditions of overvoltage or undervoltage can result in severe damage. Motors are designed to operate within a specific voltage range, and any deviation can cause inefficiency or damage.

Causes of Voltage Issues:

-

Overvoltage: Occurs when the supply voltage exceeds the motor’s rated voltage. It can cause insulation breakdown and overheating.

-

Undervoltage: When the voltage falls below the rated value, the motor will draw excessive current, leading to overheating and possible winding damage.

Prevention and Solutions:

- Use voltage regulators or automatic voltage controllers to ensure the motor operates within its rated voltage range.

- Install overvoltage and undervoltage protection devices in the electrical circuit.

- Regularly check the voltage supply to ensure it is within acceptable limits.

7. Power Supply Issues

Power supply issues, such as interruptions or fluctuations in the supply frequency, can cause serious operational problems in three-phase induction motors.

Causes of Power Supply Issues:

-

Frequency Fluctuations: The standard frequency for three-phase systems is 50 or 60 Hz. Fluctuations in frequency can cause the motor to run inefficiently or even fail.

-

Power Interruptions: Power outages or brief interruptions can disrupt motor operation, leading to starting issues or mechanical stresses when the motor restarts.

Prevention and Solutions:

- Install uninterruptible power supplies (UPS) or other power conditioning equipment to protect against power interruptions.

- Monitor and regulate supply frequency to ensure the motor operates smoothly.

8. Incorrect Installation and Wiring

Incorrect installation, improper wiring, or inadequate protection can lead to motor failures.

Causes of Incorrect Installation:

-

Incorrect Voltage Wiring: Connecting the motor to an incorrect voltage supply can damage the windings or cause overheating.

-

Improper Connection: Incorrect connection of the motor terminals, such as wrong phase sequence or neutral connections, can cause damage to the motor and the electrical system.

Prevention and Solutions:

- Follow manufacturer guidelines and hire qualified professionals for installation.

- Double-check the wiring, voltage supply, and protection devices during installation and commissioning.

Conclusion

Three-phase induction motors are durable and reliable, but they are still susceptible to failure due to several common causes. By understanding the potential issues, such as overheating, electrical imbalance, bearing failure, electrical faults, and mechanical stress, operators and maintenance personnel can take proactive measures to prevent motor damage and ensure smooth operation. Regular inspections, proper installation, and appropriate maintenance practices can go a long way in extending the life of a three-phase induction motor and improving its efficiency.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体