How Does the Efficiency of an AC Geared Motor Compare to Other Types of Motors?

In modern industrial applications, motors are essential components that drive machinery across various sectors, from manufacturing and automation to HVAC systems and automotive production. Among the most widely used types of motors are AC (Alternating Current) motors, which include both standard AC motors and AC geared motors. The efficiency of a motor is a critical consideration for businesses, as it directly impacts energy consumption, operational costs, and environmental sustainability. This article explores the efficiency of AC geared motors and compares them to other types of motors, such as DC motors and standard AC motors, to understand their relative advantages and limitations in different applications.

1. Understanding AC Geared Motors

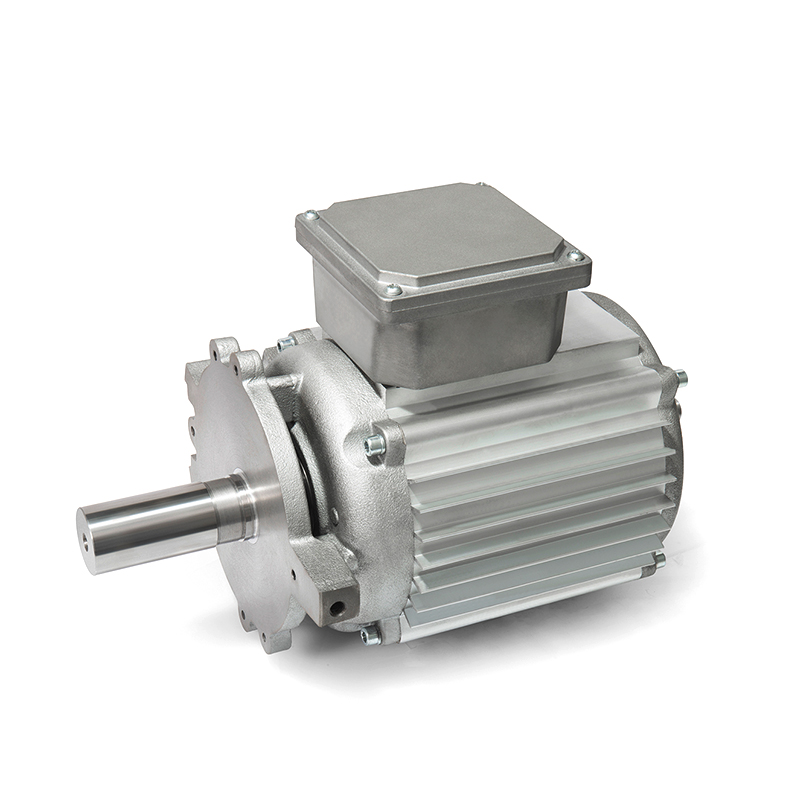

An AC geared motor is essentially a combination of two key components: an AC motor and a gearbox (or gear reducer). The motor provides the rotational force (torque), while the gear system is designed to reduce the motor’s speed and increase its torque output. This type of motor is commonly used when a specific torque or speed is required for a particular application.

The efficiency of an AC geared motor is influenced by several factors, including:

- The motor’s electrical efficiency, which is a result of the design and quality of the motor windings and components.

- The gearbox efficiency, which depends on the gear type, materials, and lubrication.

- Load conditions, as the motor’s efficiency can vary based on the load it is driving.

2. Factors Affecting Motor Efficiency

Before diving into a comparison of the efficiency of various motor types, it’s important to first understand the factors that influence motor efficiency. Some of the key factors include:

- Electrical losses: These are losses that occur due to the resistance in the motor windings and other electrical components. They are more significant in larger motors and high-speed applications.

- Mechanical losses: These include losses caused by friction in the bearings, the rotor, and other moving parts of the motor.

- Magnetic losses: These losses arise due to the magnetic field in the motor, which can result in heat generation and reduced efficiency.

- Gear losses: In the case of AC geared motors, there are additional mechanical losses due to the gearbox, which can reduce the overall efficiency of the system.

The efficiency of motors is typically expressed as a percentage, with higher percentages indicating better performance and less energy wasted. In terms of energy consumption, higher efficiency means lower operating costs and better sustainability in the long run.

3. AC Geared Motors vs. Standard AC Motors

Standard AC motors (which include induction motors and synchronous motors) are commonly used in applications where high speeds are required, and torque is not as critical. In these motors, the speed and torque output are typically fixed, meaning they are most efficient when operating under their rated conditions.

3.1 Efficiency of Standard AC Motors

- Induction motors: These are the most commonly used AC motors and are relatively efficient in most industrial settings. The efficiency of an induction motor can range from 85% to 95%, depending on the size and design of the motor. The efficiency decreases at lower loads because the motor continues to consume power even when the load is minimal.

- Synchronous motors: These motors offer higher efficiency than induction motors, particularly in applications where they operate at constant speed and power factor. Their efficiency can reach up to 98% in certain applications, especially when the load is optimal.

3.2 Efficiency of AC Geared Motors

AC geared motors, due to their integration of a gear system, typically have a lower overall efficiency than standard AC motors. The gear system, which reduces speed and increases torque, introduces additional mechanical losses (friction, heat, and wear) into the system. The efficiency of the geared motor can vary, but it usually falls in the range of 70% to 90%, depending on the gear type and the design of the motor.

However, the key advantage of the AC geared motor is its ability to provide high torque at lower speeds, making it ideal for applications requiring substantial mechanical force and reduced speed. Even though the motor’s efficiency might be slightly lower than a standard AC motor, it is still a highly efficient solution for such applications due to its ability to perform tasks that would otherwise require a larger, more energy-consuming motor.

4. AC Geared Motors vs. DC Motors

DC motors are another popular type of electric motor that is widely used in various applications, including robotics, conveyors, and electric vehicles. DC motors operate on direct current and are known for their precise speed control and high torque at low speeds.

4.1 Efficiency of DC Motors

- Brushed DC motors: These motors are commonly used in smaller applications and have efficiencies ranging from 70% to 85%, depending on the motor’s design. The presence of brushes introduces mechanical friction, which reduces their overall efficiency and lifespan.

- Brushless DC motors: These are more efficient than brushed motors, with efficiencies ranging from 85% to 90% or higher. Brushless motors eliminate the need for brushes, reducing friction and allowing for smoother, more efficient operation.

4.2 AC Geared Motors vs. DC Motors

AC geared motors and DC motors are often compared because both can provide high torque and precise control. However, DC motors generally offer better efficiency in low-speed, high-torque applications due to the direct control of speed and torque. Brushless DC motors, in particular, are highly efficient due to their design, offering efficiency rates of 90% or higher.

However, AC geared motors tend to be more suitable for applications where long-term durability, ease of maintenance, and the ability to handle larger loads are more critical. The gear system in AC geared motors may lower their efficiency slightly, but they can still be more cost-effective and reliable in certain high-torque applications, especially when synchronous or induction motors are used.

5. Efficiency Comparison: AC Geared Motors and Other Motors

Now that we’ve examined the efficiency of various types of motors, let’s summarize how AC geared motors compare to others:

- Standard AC Motors: Generally more efficient than AC geared motors because they don’t have additional mechanical losses from the gear system. Induction motors typically operate at efficiencies of 85% to 95%, while synchronous motors can reach up to 98%.

- DC Motors: Brushless DC motors are typically more efficient than AC geared motors, with efficiencies ranging from 85% to 90% or higher. However, the simplicity and cost-effectiveness of AC geared motors make them an attractive option for applications where high torque at low speeds is required.

AC geared motors, while less efficient due to the added gear system, are still highly efficient for specific applications where high torque at low speed is crucial. The gear system allows for the conversion of motor speed into a higher torque output, which is invaluable in certain industrial processes, such as conveyors, automated machinery, elevators, and pumps.

6. Energy Savings and Cost Considerations

When comparing the efficiency of AC geared motors to other types of motors, it’s important to consider not just the initial efficiency, but also the long-term energy savings. AC geared motors, while somewhat less efficient than standard AC or DC motors, are often more cost-effective in applications where torque and speed control are more important than raw efficiency. Additionally, the ability to operate at lower speeds can result in energy savings in certain settings, such as in pumps and fans that require high torque but relatively low speeds.

Moreover, the maintenance and durability of AC geared motors often make them a more cost-effective option over time, even if their efficiency is slightly lower. The reliability of AC motors, particularly in heavy-duty applications, can result in lower downtime and fewer repairs, improving the overall cost-efficiency of the system.

7. Conclusion

The efficiency of an AC geared motor compared to other types of motors, such as standard AC motors and DC motors, depends largely on the specific application. Standard AC motors tend to be more efficient in terms of raw energy consumption but may not provide the necessary torque and speed control for certain tasks. DC motors, particularly brushless DC motors, offer high efficiency and precise control, making them ideal for smaller applications that require fine-tuned performance.

However, AC geared motors provide an optimal balance between efficiency and torque output, making them indispensable for applications where high torque at low speeds is necessary. While their overall efficiency may be slightly lower than standard AC motors or DC motors, they offer durability, ease of maintenance, and cost-effectiveness that make them the best choice for many industrial applications.

In the end, the selection of a motor type should always be based on the specific requirements of the task at hand, including torque, speed, efficiency, and long-term cost-effectiveness. By carefully evaluating these factors, businesses can select the most efficient motor that aligns with both their performance needs and budget considerations.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体