What are the advantages of AC gear motors? What industries are they suitable for?

In the fields of modern industrial automation, smart devices and home appliance manufacturing, AC gear motors are increasingly being used. It uses AC power as the driving source and combines a reduction gear mechanism to convert the high-speed and low-torque output of the motor into low-speed and high-torque, meeting a variety of low-speed and high-load application scenarios.

1. What is an AC gear motor?

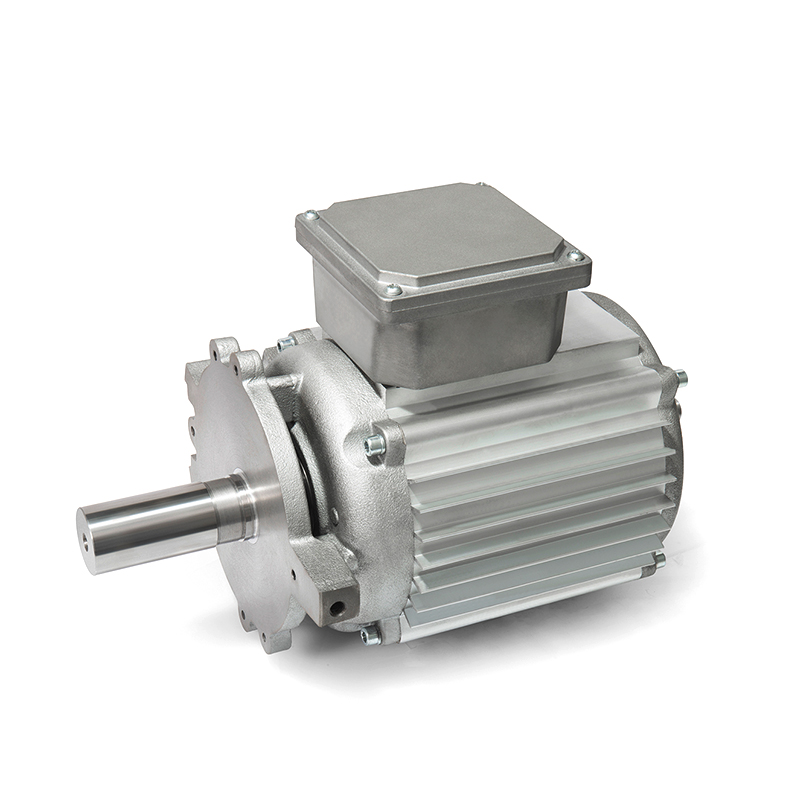

An AC gear motor is a power transmission device that combines an AC motor with a reducer. The internal gear system is used to reduce the speed of the motor output, thereby increasing the output torque. Common power supply voltages include 220V, 380V, etc., which are suitable for single-phase or three-phase AC systems.

2. What are the core advantages of AC gear motors?

1. High torque output, suitable for heavy-duty work

The reduction mechanism can greatly increase the torque output of the motor, which is suitable for mechanical equipment with large starting resistance and continuous output power, such as conveyor belts, mixing equipment, etc.

2. Strong stability and smooth operation

Compared with DC motors or stepper motors, AC gear motors run more smoothly, are not prone to speed jitter, and are suitable for continuous long-term work.

3. Compact structure and save installation space

The integrated design of the motor and the reducer greatly reduces the volume, which has obvious advantages in space-constrained equipment.

4. Relatively low cost and convenient maintenance

Compared with servo motors or frequency conversion systems, AC gear motors have more cost advantages and are relatively easy to maintain, suitable for large-scale industrial equipment installation and use.

5. Diverse types and complete models

Whether it is single-phase or three-phase power supply requirements, from small 60W to large 5KW or above equipment, suitable specifications of AC gear motors can be found on the market.

3. What are the main industries for AC gear motors?

1. Automated conveying system

Such as food packaging lines, electronic assembly lines, express logistics conveyor lines, etc., motors with gear reduction are widely used to achieve stable and uniform transportation.

2. Industrial machinery manufacturing

In metal processing, plastic molding, woodworking machinery and other equipment, AC gear reduction motors are often used for spindle drive, feeding system, lifting system, etc.

3. Agricultural and livestock equipment

In automatic feed systems, greenhouse ventilation systems, and automatic irrigation devices, low-speed and high-torque gear motors are particularly suitable.

4. Door control equipment and lifting systems

Garage doors, lifting platforms, electric curtains, stage equipment and other occasions require quiet, stable and self-locking reduction motors.

5. Home appliances

For example, elderly power chairs, electric clothes drying racks, massage chairs, etc., have high requirements for speed control and stability.

4. How to choose a suitable AC gear reduction motor?

The following factors need to be considered comprehensively when selecting:

| Parameter Category | illustrate |

| Motor power | Choose according to load size, such as common 60W, 90W, 120W, 200W, etc. |

| Reduction ratio | Determine the output speed, such as 1:10, 1:30, 1:50 and other common ratios |

| Output torque | Must meet the load requirements of the driven equipment |

| Installation | Whether flange installation, foot installation, etc. are required |

| Voltage Type | Single-phase 220V, three-phase 380V, etc. |

| Protection level | If you need waterproof and dustproof, choose IP54 or above |

| Usage Environment | Whether it is a high temperature, high humidity, or dusty environment, additional consideration should be given to heat dissipation and sealing. |

5. Comparison of AC gear reduction motors with other types of motors

| type | advantage | shortcoming | Typical Applications |

| AC Gear Motor | Low cost, compact structure, high torque | Speed regulation is not as accurate as servo motor | Conveyor lines, agricultural equipment |

| DC Gear Motor | Flexible control and adjustable speed | Carbon brushes wear quickly and have a short lifespan | Small robots, electric windows |

| Stepper Motor | High control accuracy | Easy to heat up, no closed-loop control | Printing equipment, 3D printer |

| Servo Motor | High precision and fast response | High cost and complex system | High-end automation, CNC |

6. Future development trend: AC gear motors will be smarter and more energy-efficient

With the development of Industry 4.0, traditional AC gear reduction motors are also gradually developing towards intelligence and networking:

Intelligent control: integrated sensors and remote control functions to achieve operating status monitoring and remote diagnosis.

High-efficiency energy-saving design: using high-efficiency iron cores, low-energy consumption coils and advanced lubrication structures to reduce energy consumption.

Customized solutions: can customize the reduction ratio, output shaft direction, installation method, etc. according to customer needs.

7. Conclusion

Although AC gear reduction motors are a traditional power equipment, they still play an irreplaceable role in the current trend of intelligent manufacturing and equipment automation. With its simple structure, stable and reliable, high cost-effectiveness and other advantages, they are widely used in many industries. For enterprises, the reasonable selection and correct use of AC gear reduction motors can not only improve the operating efficiency of equipment, but also reduce long-term operation and maintenance costs.

Do you know whether your equipment is suitable for using AC gear motors? Have you considered choosing the right reduction ratio to improve efficiency? Maybe now is a good time to upgrade.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体