What Causes a Single-phase Induction Motor to Hum But Not Start?

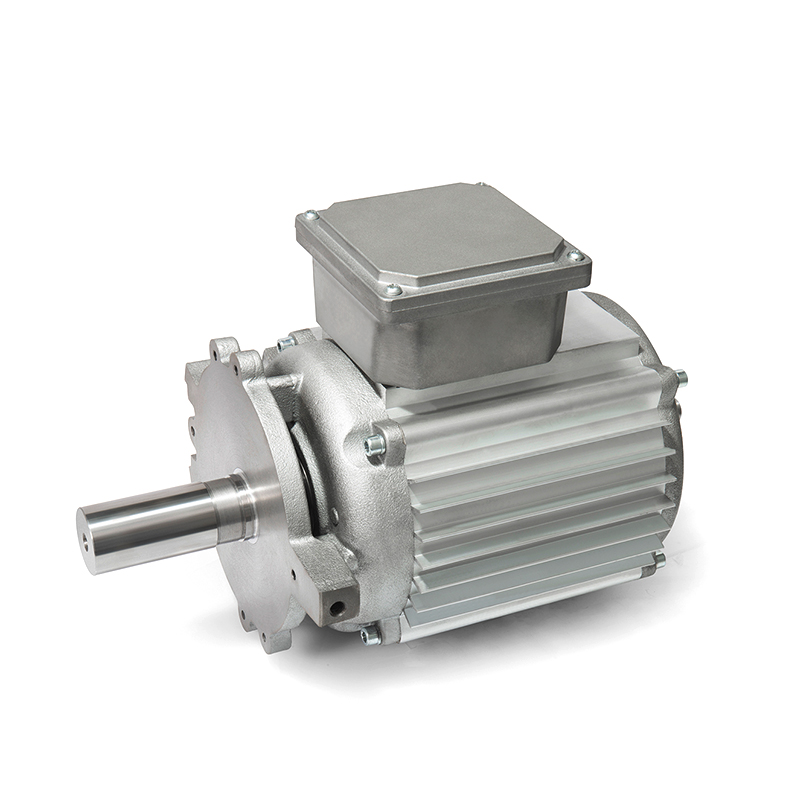

A single-phase induction motor is a workhorse in residential, agricultural, and light industrial applications. It’s commonly used in ceiling fans, pumps, compressors, air conditioners, and various small machines. However, one of the most common issues encountered is when the motor hums but does not start.

This behavior can be frustrating and, if not diagnosed properly, may lead to permanent damage. This article explores the underlying causes, diagnostic methods, and solutions for when a single-phase induction motor hums but fails to start.

1. How a Single-phase Induction Motor Starts

Before diving into the issue, it’s important to understand how these motors operate:

-

Single-phase induction motors inherently do not have a self-starting mechanism due to the lack of a rotating magnetic field.

-

To overcome this, they use an auxiliary starting winding, often with a start capacitor or centrifugal switch to generate phase shift and produce torque at startup.

-

Once the motor reaches ~75% of its rated speed, the start mechanism disconnects, and the motor continues to run using the main winding alone.

If any part of this starting mechanism fails, the motor will hum due to electrical current but will not rotate.

2. Common Causes of Humming Without Starting

A. Faulty Start Capacitor

This is the most common cause.

-

The start capacitor provides the phase shift necessary for initial torque.

-

If it fails or leaks, the auxiliary winding does not get enough current, and the motor can’t rotate.

Symptoms:

-

Motor makes a low-pitch hum

-

Sometimes accompanied by overheating

-

Rotor doesn’t spin unless manually pushed (dangerous)

Solution:

Test the capacitor with a multimeter in capacitance mode. If the reading is significantly below the rated value or shows open, replace it.

B. Defective Centrifugal Switch or Start Relay

In split-phase or capacitor start motors, a centrifugal switch or relay disconnects the start winding once the motor is running.

-

If it’s stuck open, the start winding never energizes.

-

If stuck closed, the motor may overheat.

Symptoms:

-

Humming, no rotation

-

May buzz louder than a capacitor issue

-

A burning smell in severe cases

Solution:

Inspect the centrifugal switch/relay for physical damage, contact wear, or improper alignment. Clean or replace as needed.

C. Seized Rotor or Mechanical Jam

If the motor shaft or load is mechanically jammed, the motor may hum but cannot overcome the resistance to start.

Symptoms:

-

Humming noise with no movement

-

High current draw

-

Tripped circuit breakers or blown fuses

Solution:

-

Disconnect the motor from its load (e.g., belt or pump)

-

Try rotating the shaft manually (with power off)

-

If it’s stiff, inspect for bearing failure, rust, or dirt accumulation

D. Winding Failure (Open or Shorted)

If either the start winding or run winding is damaged:

-

The motor might still energize and hum

-

But lacks enough torque or balance to rotate

Symptoms:

-

Motor hums but no motion

-

Motor gets hot quickly

-

Burning smell or smoke in severe cases

Solution:

Use a multimeter to check winding resistance. If open or shorted, the motor will likely need rewinding or replacement.

E. Low Voltage or Undersized Power Supply

Induction motors require a surge of current at startup. If:

-

The supply voltage is low

-

Or the wire gauge is too small

The motor may fail to generate enough torque.

Symptoms:

-

Humming starts immediately when turned on

-

Other appliances may flicker or dim

-

Motor starts when used on a different outlet or line

Solution:

-

Measure voltage at the motor terminals

-

Ensure it matches the rated voltage ±10%

-

Upgrade wiring or check the breaker load

F. Stuck Rotor or Bad Bearings

Over time, bearing wear, dust, or lubrication loss may cause the rotor to stick.

Symptoms:

-

Motor hums, rotor does not move

-

Shaft is hard to turn manually

-

May produce grinding or squealing noise

Solution:

-

Clean and lubricate the bearings

-

Replace worn bearings or sleeves

-

Re-align the shaft and end bells

3. Safety Tip: Don’t Force It!

It’s tempting to manually spin the shaft to "kick-start" a humming motor — this is dangerous.

-

Motors may suddenly engage, risking injury

-

If the capacitor is faulty, repeated trials may damage the windings

-

High startup current can overheat the motor

Always disconnect power and use proper diagnostic tools before testing.

4. Diagnostic Flowchart

Here’s a simplified troubleshooting flow for a humming single-phase motor:

| Step | Action | Diagnosis |

| 1 | Listen for humming | Confirms coil is energized |

| 2 | Try rotating shaft (power off) | If stuck, check bearings/jam |

| 3 | Test start capacitor | Replace if faulty |

| 4 | Check centrifugal switch/relay | Clean or replace if damaged |

| 5 | Measure supply voltage | Upgrade wiring if low |

| 6 | Test windings for continuity | Repair or replace motor |

5. Real-World Examples

Example 1: Ceiling Fan Won’t Start

-

Symptom: Humming noise, no blade movement

-

Cause: Failed capacitor

-

Fix: Replaced 2.5 µF capacitor → Fan works perfectly

Example 2: Air Compressor Motor Hums

-

Symptom: Loud hum, breaker trips

-

Cause: Jammed piston + bad capacitor

-

Fix: Lubricated piston, replaced capacitor

6. How to Prevent Future Issues

-

Use motors within rated voltage/current

-

Keep the motor clean and dust-free

-

Lubricate bearings regularly

-

Install a thermal overload protector

-

Avoid long extension cords which drop voltage

7. When to Replace the Motor

If the motor:

-

Has multiple failed components (windings + bearings)

-

Is older than 10–15 years

-

Requires more repair cost than a new unit

it’s often more cost-effective to replace it with a new, efficient model.

Conclusion

A single-phase induction motor that hums but does not start is a clear indication of a starting circuit problem, mechanical blockage, or electrical failure. The most common culprit is a faulty capacitor, but issues with the centrifugal switch, voltage supply, or rotor can also cause similar symptoms.

By following a structured diagnostic process, and using basic tools like a multimeter, you can pinpoint the issue and restore motor functionality — or decide when a replacement is the better option.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体