What Are the Key Applications of AC Geared Motors in Industrial Machinery?

AC geared motors are integral components in various industrial applications, offering significant benefits in terms of power transmission and operational efficiency. These motors combine the functionality of an AC motor with a gear reducer, providing the necessary torque and speed adjustments for various types of machinery. In this article, we explore the key applications of AC geared motors, focusing on their versatility and effectiveness in enhancing industrial operations.

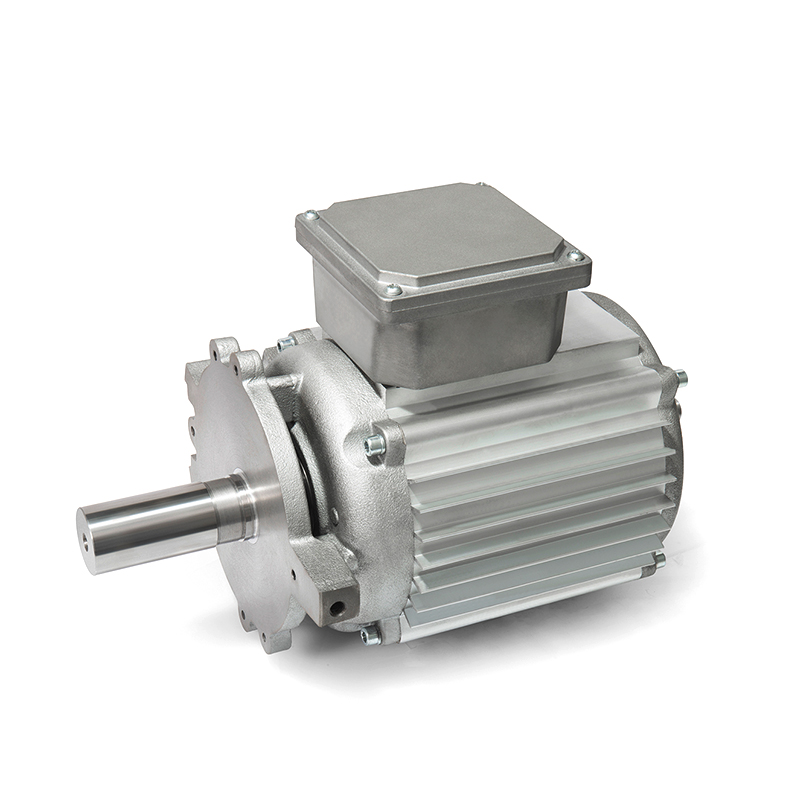

Understanding AC Geared Motors

Before diving into specific applications, it is important to understand the basic function of AC geared motors. These motors use alternating current (AC) as a power source and are paired with a gearbox that adjusts the speed and torque of the motor's output. This combination allows for precise control of machinery, making AC geared motors an ideal choice for applications that require consistent and reliable performance over extended periods.

AC geared motors are commonly used in environments where precise motion control, high torque, and long-term reliability are required. They are engineered for use in heavy-duty machines and are available in various configurations, making them adaptable to many industrial sectors.

Key Features of AC Geared Motors

- High torque output for heavy-duty applications.

- Variable speed control for enhanced precision.

- Energy-efficient operation, reducing power consumption.

- Durability and long service life in challenging environments.

- Compact design, ideal for space-constrained installations.

Applications of AC Geared Motors in Industrial Machinery

Material Handling Systems

One of the most significant applications of AC geared motors is in material handling systems. These systems are critical for industries that deal with the movement of raw materials, finished products, or heavy equipment. AC geared motors are used to power conveyor belts, hoists, lifts, and other machinery used to move goods efficiently and safely through production lines.

The ability of AC geared motors to provide constant torque and variable speed makes them ideal for applications that require smooth and controlled motion, such as in packaging or palletizing systems. Their energy efficiency and ability to handle heavy loads also contribute to reducing operational costs in material handling applications.

Pumps and Compressors

AC geared motors are also widely used in pumps and compressors, particularly in applications that require continuous operation and reliable performance. In industries such as water treatment, oil and gas, and HVAC systems, pumps powered by AC geared motors are used to transport fluids and gases at a consistent rate. The gearbox in the motor helps to optimize the speed and torque, ensuring that the pump operates efficiently under various load conditions.

For example, in water treatment plants, AC geared motors are often used to drive pumps that move water through filtration systems. Their ability to operate at different speeds allows for better control of flow rates, while their rugged design ensures that they can withstand the harsh environments typical in these applications.

Conveyor Systems in Manufacturing

In manufacturing environments, AC geared motors play a crucial role in driving conveyor systems that move parts and materials through different stages of production. These motors are used in various sectors, including automotive, electronics, and food processing. By adjusting the motor’s speed and torque, manufacturers can optimize the movement of goods, improving production line efficiency.

AC geared motors in conveyor systems ensure precise control of materials, enabling smooth transitions between different stages of assembly or packaging. Additionally, they can be integrated with sensors and control systems for automated operations, further enhancing production efficiency and reducing human error.

Automated Robotics and Assembly Lines

AC geared motors are essential in automated robotics and assembly lines, where precision, speed, and reliability are crucial. These motors are used to drive robotic arms, turntables, and other moving parts in assembly systems. The combination of an AC motor and gear reducer allows for fine-tuned control over movement, which is critical for assembling complex products or performing repetitive tasks with high accuracy.

In robotic applications, the gear reduction offered by AC geared motors enables robots to handle heavier loads and operate with greater stability, even at higher speeds. This makes them ideal for tasks such as pick-and-place operations, sorting, and material handling in industries ranging from automotive manufacturing to electronics assembly.

Textile Industry

The textile industry is another sector that benefits from the use of AC geared motors. These motors are used to drive machinery such as spinning machines, weaving looms, and dyeing machines. The textile manufacturing process requires precise control over speed and torque to ensure the quality of the fabric and to prevent machine failure or damage to delicate fibers.

In textile mills, AC geared motors are valued for their reliability and ability to operate continuously under demanding conditions. Their ability to provide consistent power over long periods helps to reduce downtime, improving overall productivity and reducing the cost of maintenance.

Food Processing and Packaging

AC geared motors are commonly used in food processing and packaging industries, where consistent performance and hygiene are essential. These motors drive conveyors, mixers, slicers, and other equipment that is used in food preparation and packaging. In many cases, AC geared motors are preferred due to their ability to deliver precise control and energy efficiency in environments that require continuous operation.

Additionally, in packaging lines, AC geared motors help control the speed and accuracy of filling, sealing, and labeling machines. Their durability and resistance to wear ensure that they can withstand the high-speed demands of these systems without compromising the quality of the packaged products.

Conclusion

AC geared motors are a key component in a wide range of industrial applications, offering high torque, precise speed control, and energy-efficient operation. From material handling to automated robotics and food processing, these motors enhance the performance of machinery across various sectors. Their versatility, combined with their rugged durability, makes them an ideal choice for industries that require reliable, long-term solutions for power transmission and motion control. As industries continue to evolve, AC geared motors will remain an essential part of the machinery landscape, driving innovation and efficiency in industrial operations.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体