Why Is the Car Wash AC Geared Motor the Power Behind Efficient and Reliable Cleaning Systems?

In the fast-growing car care industry, automation and precision are the keys to efficiency, consistency, and customer satisfaction. At the heart of every automatic car wash system lies a powerful yet often overlooked component — the Car Wash AC Geared Motor. This essential machine part drives brushes, conveyors, and pumps with consistent torque and speed, ensuring that vehicles are cleaned smoothly, safely, and efficiently.

But what exactly is a Car Wash AC Geared Motor? How does it function, and why is it so vital in modern car wash equipment? In this article, we’ll explore the design, operation, advantages, and applications of AC geared motors in the car wash industry — revealing why they are indispensable for smooth-running, high-performance washing systems.

1. What Is a Car Wash AC Geared Motor?

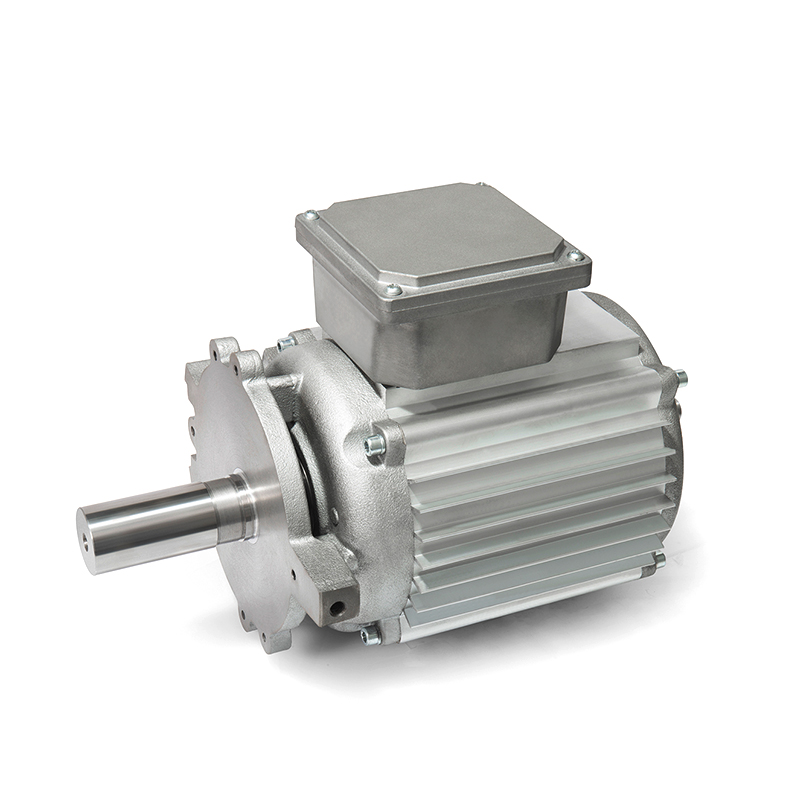

A Car Wash AC Geared Motor is a combined unit of an electric motor and a gearbox (gear reducer) designed specifically to provide controlled torque and rotational speed in automatic car wash systems.

The AC (alternating current) motor converts electrical energy into mechanical motion, while the gearbox adjusts the output speed and torque according to the operational needs — such as rotating brushes, driving conveyors, or controlling mechanical arms.

In essence, this motor is the power source that drives the motion of many moving parts inside an automatic car wash system. Its precision and reliability directly affect washing quality, energy consumption, and system lifespan.

2. How Does an AC Geared Motor Work?

The operation of a Car Wash AC Geared Motor involves two main components working seamlessly together:

(1) The AC Motor

An AC motor operates by using alternating current to produce a rotating magnetic field. This field induces torque in the rotor, which converts electrical energy into rotational motion. AC motors used in car wash systems are usually three-phase induction motors, known for their efficiency, robustness, and simple design.

(2) The Gearbox

The gearbox (or gear reducer) is attached to the motor’s output shaft. It contains a set of gears that reduce the motor’s high speed while multiplying its torque. The result is a controlled and powerful output that can handle heavy mechanical loads with precision.

Together, the motor and gearbox ensure that each component in the car wash — from the rotating brushes to conveyor belts — moves at the right speed and with the right force.

3. Why Is the Geared Motor So Important in Car Wash Systems?

Automatic car wash systems involve a complex series of synchronized movements. Each step — washing, brushing, rinsing, and drying — requires precise mechanical control.

The AC geared motor plays a vital role by:

- Driving rotary brushes: It powers the circular brushes that clean the vehicle’s exterior with controlled pressure.

- Operating conveyors: It moves the vehicle smoothly through the washing tunnel.

- Controlling water pumps and dryers: It ensures steady operation of fluid and air systems.

- Maintaining speed synchronization: It coordinates multiple moving components for consistent cleaning.

Without geared motors, car wash systems would lack the precision, stability, and torque needed to perform multiple cleaning operations efficiently and safely.

4. Structural Design of a Car Wash AC Geared Motor

A Car Wash AC Geared Motor is engineered for both performance and durability in wet, humid, and sometimes chemically harsh environments. Its key components include:

- Motor Housing: Typically made of cast aluminum or stainless steel to resist corrosion.

- Rotor and Stator Assembly: The main electrical components that generate motion.

- Gearbox: Contains helical, worm, or planetary gears for torque transmission and speed reduction.

- Shaft Seals and Bearings: Provide smooth rotation while preventing water or detergent ingress.

- Cooling Fan or Fins: Help dissipate heat during continuous operation.

- Protective Coating: Often IP65 or higher rating to ensure waterproof and dustproof performance.

This robust structure allows the motor to operate continuously in demanding car wash environments with minimal maintenance.

5. Types of AC Geared Motors Used in Car Wash Systems

There are several types of geared motors used in automatic car wash machines, each tailored for specific applications:

A. Helical Geared Motors

- High efficiency and smooth operation.

- Ideal for driving car wash brushes or rollers.

B. Worm Geared Motors

- Compact design and high torque output.

- Commonly used for conveyors and lifting mechanisms.

C. Planetary Geared Motors

- High power density and precision.

- Suitable for robotic arms or automated washing tools.

D. Right-Angle Geared Motors

- Used when space is limited, as they allow 90° torque transmission.

- Ideal for side brushes or corner operations.

By selecting the appropriate motor type, car wash manufacturers can balance power, efficiency, and compact design.

6. Key Features of a High-Quality Car Wash AC Geared Motor

A modern AC geared motor designed for car wash applications incorporates advanced technologies and protective designs to ensure long-lasting performance. Typical features include:

- IP65–IP67 Waterproof Rating: Protects the motor from water, detergent, and high humidity.

- Corrosion-Resistant Housing: Aluminum or stainless-steel casing ensures longevity.

- High Torque Output: Enables smooth, consistent brush and conveyor operation.

- Energy Efficiency: Optimized motor design minimizes electricity consumption.

- Low Noise and Vibration: Ensures a quiet and smooth washing experience.

- Thermal Protection: Prevents overheating during prolonged operation.

- Compact Design: Fits easily within limited mechanical spaces.

These features allow the motor to withstand the rigors of continuous operation in commercial car wash environments.

7. Applications of Car Wash AC Geared Motors

AC geared motors are used throughout both tunnel-type and automatic gantry car wash systems. Common applications include:

(1) Brush Rotation Systems

The main and side brushes rely on geared motors to rotate at controlled speeds, ensuring thorough yet gentle cleaning of the vehicle’s surface.

(2) Conveyor Systems

Geared motors drive the belts or rollers that guide vehicles through the car wash tunnel at a consistent pace.

(3) Water Pump Drives

Motors power high-pressure pumps that deliver water and cleaning solutions evenly across the vehicle.

(4) Drying Fans and Blowers

High-torque motors operate blowers to remove water efficiently after rinsing.

(5) Lifting Mechanisms

Certain motors control the vertical movement of brushes or robotic arms, adapting to different vehicle sizes.

Each function demands precise torque and speed control — a capability made possible by the geared motor’s engineering.

8. Advantages of Using AC Geared Motors in Car Wash Systems

Switching to AC geared motors provides a wide range of benefits for manufacturers and operators:

1. Consistent Performance

Unlike DC motors, AC geared motors deliver stable torque and speed, even under variable loads.

2. Long Service Life

With minimal wear components and strong construction, these motors can operate for years with minimal maintenance.

3. Energy Efficiency

High-efficiency designs reduce power consumption, lowering operating costs.

4. Compact and Flexible Design

Integrated gearboxes reduce space requirements and simplify installation.

5. High Torque at Low Speed

Essential for heavy loads such as rotating brushes and conveyor systems.

6. Smooth and Quiet Operation

Precision gears and balanced rotors ensure quiet performance — important for customer comfort.

7. Reliability in Harsh Environments

Sealed housings, waterproofing, and corrosion resistance allow operation even in water-intensive conditions.

These advantages make AC geared motors the preferred choice for modern car wash systems.

9. Maintenance and Safety Tips

Proper care of geared motors ensures optimal performance and long lifespan. Some essential maintenance steps include:

- Regular Lubrication: Ensure gears and bearings are properly greased.

- Inspect Seals and Covers: Prevent water ingress into electrical components.

- Check Mounting and Alignment: Misalignment can cause vibration or wear.

- Monitor Temperature: Avoid overheating by maintaining proper ventilation.

- Schedule Periodic Cleaning: Remove dust and detergent residue from motor surfaces.

- Replace Worn Brushes or Bearings Promptly: To prevent downtime.

Adhering to these practices ensures continuous, safe operation of the car wash system.

10. The Role of Automation and Smart Technology

Modern car wash systems are increasingly integrating smart control technology with geared motors. These intelligent systems allow:

- Variable Frequency Drives (VFDs): Adjust motor speed dynamically for energy efficiency.

- Remote Monitoring: Track motor performance and detect issues in real-time.

- Predictive Maintenance: Use sensors to predict failures before they occur.

- Energy Optimization: Automatically adjust motor load based on system demand.

Such innovations not only enhance performance but also support green, energy-efficient operations, reducing environmental impact and maintenance costs.

11. Future Trends in Car Wash Geared Motor Technology

As the car wash industry evolves, so too does the technology behind its motors. Key emerging trends include:

- Compact, Integrated Motor Systems: Combining multiple mechanical functions into one drive unit.

- Eco-Friendly Motors: Designs that use recyclable materials and energy-saving components.

- Smart Diagnostics: AI-based systems for fault detection and maintenance alerts.

- Noise Reduction Engineering: Advanced materials for near-silent operation.

- High-Temperature and Chemical Resistance: For extreme wash conditions and cleaning agents.

These developments are setting new standards for performance, sustainability, and efficiency.

Conclusion: The Power Behind Every Perfect Wash

So, why is the Car Wash AC Geared Motor the power behind efficient and reliable cleaning systems?

Because it transforms electrical energy into precise mechanical motion — powering every brush, belt, and blower that brings vehicles to a spotless shine.

From its rugged design to its smooth performance, the geared motor is the driving force that keeps automatic car washes running flawlessly day after day. Its reliability ensures that operators can serve customers faster, reduce maintenance downtime, and maintain consistent cleaning quality.

In the modern era of smart automation and eco-conscious technology, the Car Wash AC Geared Motor remains a symbol of industrial innovation — combining power, precision, and durability to deliver the clean that every car deserves.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体