Brushless vs. Brushed Motors in Cleaning Machines: Which Cleans Up Better?

Introduction

Motors are at the heart of every cleaning machine, whether it’s a powerful upright vacuum, a compact robotic vacuum, or a versatile floor scrubber. The type of motor inside directly impacts performance, efficiency, noise level, and long-term reliability. Two main motor technologies dominate the cleaning machine industry today: brushed motors and brushless motors.

While both have been used for decades, the shift toward cordless and robotic cleaners has sparked renewed debate about which technology offers the best results for modern cleaning needs. This article explores the differences between brushed and brushless motors, focusing on their role in vacuum cleaners, floor scrubbers, carpet cleaners, and robotic cleaners. By understanding how each motor type works and performs, you can make an informed decision when choosing your next cleaning machine.

What Are Brushed Motors?

Brushed motors are one of the oldest and most widely used motor designs. They operate on a straightforward principle: electrical energy is converted into mechanical motion through direct contact between internal components.

How Brushed Motors Work

A brushed motor contains three essential parts:

Commutator – A rotating switch that reverses the direction of current in the motor windings, ensuring continuous rotation.

Brushes – Carbon or graphite blocks that maintain electrical contact with the commutator.

Armature – The rotating part of the motor (rotor) that interacts with the magnetic field to generate motion.

When electricity flows through the armature windings, it creates a magnetic field that interacts with the permanent magnets or stator field, causing the rotor to spin. The brushes and commutator work together to switch current direction, allowing the motor to maintain rotation.

Advantages of Brushed Motors

Despite being an older technology, brushed motors still have several advantages in cleaning machines:

Simple Design – The construction is straightforward, making them easy to manufacture and integrate into different types of cleaning machines.

Lower Manufacturing Cost – Brushed motors are typically cheaper to produce, making them common in entry-level or budget-friendly vacuums and carpet cleaners.

Easy Control – Speed and torque can be controlled simply by adjusting voltage, which suits basic cleaning devices.

Disadvantages of Brushed Motors

However, brushed motors also come with notable drawbacks that affect their performance and longevity:

Lower Efficiency – Friction between brushes and commutator wastes energy as heat, reducing overall motor efficiency.

Maintenance Requirements – Brushes wear down over time and need periodic replacement, leading to higher maintenance costs.

Shorter Lifespan – Because of mechanical wear, brushed motors generally have a shorter operating life compared to brushless motors.

Noise – The friction between brushes and commutator creates more noise, which can make vacuums and floor cleaners louder.

For these reasons, brushed motors are still common in cost-effective or mid-range cleaning machines, but many brands are shifting toward brushless motors for premium and high-performance models.

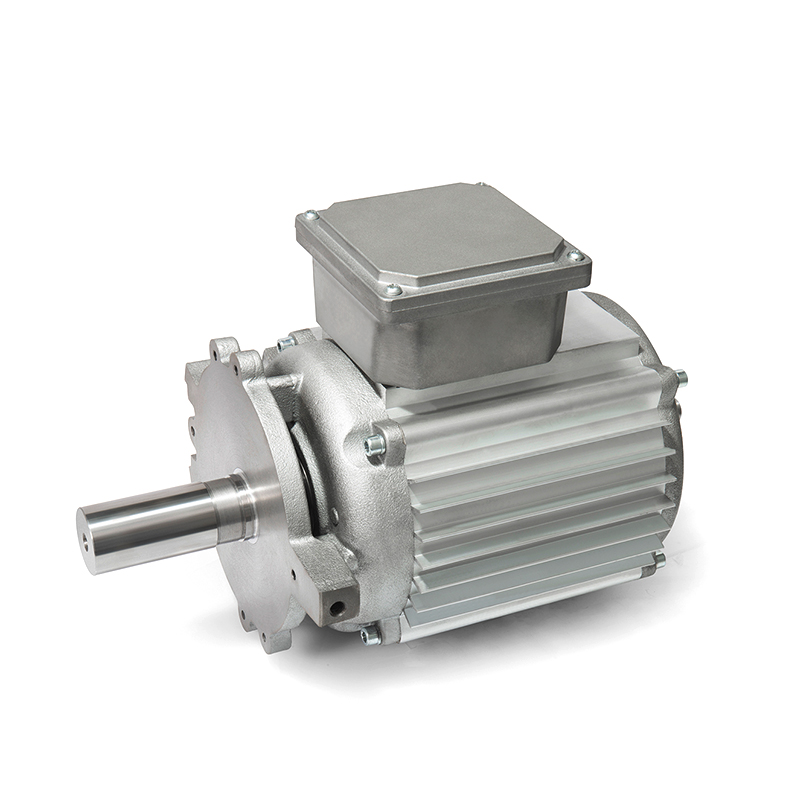

What Are Brushless Motors?

Brushless motors, often abbreviated as BLDC motors (Brushless Direct Current motors), represent a more modern advancement in motor technology. As the name suggests, they eliminate the need for brushes and a commutator, replacing them with an electronic controller that manages current flow. This innovation improves efficiency, lifespan, and overall performance, making brushless motors the preferred choice in many of today’s premium cleaning machines.

How Brushless Motors Work

Instead of brushes and a commutator, brushless motors rely on:

Permanent Magnets – These are mounted on the rotor (the rotating part).

Electronic Controller – This replaces the commutator, electronically switching current in the stator windings to keep the rotor spinning.

The absence of brushes eliminates mechanical friction, resulting in smoother and more efficient operation. The electronic controller also allows precise adjustment of speed, torque, and direction.

Advantages of Brushless Motors

Brushless motors bring several performance benefits that make them increasingly popular in vacuum cleaners, robotic cleaners, and cordless cleaning devices:

Higher Efficiency – With no energy lost to brush friction, brushless motors deliver more power per watt of electricity. This efficiency translates into stronger suction in vacuums and longer battery life in cordless cleaners.

Longer Lifespan – The lack of brushes means fewer wear-and-tear components. Brushless motors can last up to 10 times longer than brushed motors when properly maintained.

Low Maintenance – No brushes to replace means fewer service needs, making them cost-effective in the long term.

Quieter Operation – The smooth, brush-free design reduces noise, an important feature for household cleaners like robotic vacuums that run frequently.

Advanced Control – Brushless motors allow for sophisticated motor control, enabling cleaning machines to adjust power automatically based on floor type, dirt levels, or battery condition.

Disadvantages of Brushless Motors

Despite their many advantages, brushless motors are not without drawbacks:

Higher Initial Cost – The use of permanent magnets and an electronic controller makes brushless motors more expensive to produce.

Complex Control Systems – They require advanced electronics, which can increase repair costs if something goes wrong.

These factors mean that while brushless motors are the gold standard in high-end and robotic cleaners, brushed motors still maintain a place in budget-friendly models where affordability is key.

Key Differences Between Brushed and Brushless Motors

When evaluating cleaning machine motors, one of the most critical comparisons is between brushed motors and brushless motors. Although they serve the same fundamental purpose—converting electrical energy into mechanical motion—their designs, performance, and applications differ significantly.

1. Design and Working Principle

Brushed Motors rely on brushes and a commutator to switch the direction of current in the rotor windings, which keeps the motor turning. This mechanical contact generates friction and wear over time.

Brushless Motors, on the other hand, eliminate brushes and use an electronic controller to switch current in the stator windings. Permanent magnets on the rotor interact with the magnetic field, resulting in smoother rotation.

Key takeaway: Brushed motors are mechanically simpler but wear out faster, while brushless motors are electronically more advanced and longer-lasting.

2. Efficiency and Performance

Brushed Motors tend to lose more energy to heat and friction caused by the brushes. They can still provide strong torque but at the cost of efficiency.

Brushless Motors achieve much higher efficiency because there is no brush friction. This translates into more power for suction in vacuum cleaners and longer operating times in cordless devices.

Key takeaway: Brushless motors deliver better energy efficiency and higher overall performance.

3. Lifespan and Maintenance

Brushed Motors typically last for hundreds of hours before the brushes wear down and need replacement. Regular maintenance is required to keep them running smoothly.

Brushless Motors can last thousands of hours since they have no brushes to wear out. They also require little to no maintenance.

Key takeaway: For long-term durability, brushless motors clearly outperform brushed ones.

4. Cost and Complexity

Brushed Motors are inexpensive to produce and easy to repair, making them a cost-effective choice for entry-level cleaning machines.

Brushless Motors are more costly due to the permanent magnets and electronic control systems they require. If the controller fails, repairs can also be more expensive.

Key takeaway: Brushed motors are budget-friendly, while brushless motors come at a premium but justify the cost with performance.

5. Applications in Cleaning Machines

Brushed Motors are commonly found in affordable upright vacuums, industrial floor sweepers, and machines where cost is a bigger factor than long-term durability.

Brushless Motors dominate in high-end vacuums, robotic cleaners, cordless stick vacuums, and commercial-grade cleaning devices that demand efficiency, quiet operation, and extended lifespan.

In summary, brushed motors still play a role in low-cost, entry-level machines, but brushless motors are becoming the preferred standard for modern, premium cleaning solutions due to their efficiency, lifespan, and smart control features.

Which Motor Type is Right for You?

Choosing between a brushed motor and a brushless motor largely depends on your cleaning needs, budget, and preferences. Different types of cleaning machines place varying demands on motor performance, and understanding these factors will help you make the right choice.

1. Budget Considerations

Brushed Motors – Ideal for cost-conscious buyers. These motors are commonly found in budget-friendly vacuum cleaners, carpet cleaners, and entry-level floor scrubbers. They offer reliable performance for everyday cleaning without a high upfront cost.

Brushless Motors – Best suited for those willing to invest in higher-quality, long-lasting machines. While the initial cost is higher, the extended lifespan and reduced maintenance often make them more cost-effective over time.

2. Performance Requirements

Suction Power (Vacuum Cleaners) – Brushless motors provide stronger, more consistent suction and are particularly beneficial in high-performance upright vacuums, cordless stick vacuums, and robotic cleaners.

Agitation (Floor Scrubbers) – Brushless motors maintain steady torque for floor scrubbing, ensuring uniform cleaning on hard surfaces. Brushed motors can work but may lose efficiency under heavy load.

Durability (Carpet Cleaners) – For machines that encounter high friction, such as deep carpet cleaners, brushless motors outperform brushed motors in lifespan and consistency.

3. Maintenance Preferences

Low Maintenance Needs – Brushless motors are ideal for those who prefer minimal upkeep. No brushes to replace means fewer service interruptions and long-term reliability.

Willing to Maintain – If you don’t mind replacing brushes occasionally, brushed motors are still a practical choice. Routine maintenance is simple and inexpensive.

4. Noise and Comfort

Quieter Operation – Brushless motors run smoothly and quietly, making them perfect for robotic vacuums or home environments where noise is a concern.

Moderate Noise – Brushed motors generate more noise due to friction, which is acceptable in industrial or budget residential machines but may be less desirable in quiet home settings.

5. Battery Life (Cordless Cleaning Devices)

Brushless Motors – Because of higher efficiency, they consume less battery power, extending runtime in cordless vacuums, handheld cleaners, and floor mops.

Brushed Motors – Less efficient, leading to shorter battery life in battery-operated machines.

6. Recommended Applications by Cleaning Machine Type

| Cleaning Machine | Brushed Motor | Brushless Motor |

| Upright Vacuum | Entry-level or budget models | High-performance models |

| Cordless Stick Vacuum | Not recommended | Recommended for extended runtime |

| Robotic Vacuum | Basic models | Preferred for efficiency, quiet operation, and durability |

| Floor Scrubber | Budget-friendly domestic units | High-end residential or commercial units |

| Carpet Cleaner | Standard residential units | Machines needing durability and consistent power |

In summary:

Choose brushed motors if budget is a priority, the device is low to moderate use, or you are comfortable with occasional maintenance.

Choose brushless motors if you want superior efficiency, long lifespan, minimal maintenance, quiet operation, and better battery performance in cordless machines.

Selecting the right motor ensures that your cleaning machine meets your expectations for power, longevity, and ease of use, while also matching your budget.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体