How Do You Choose the Right Brushless DC Motor for Your Application?

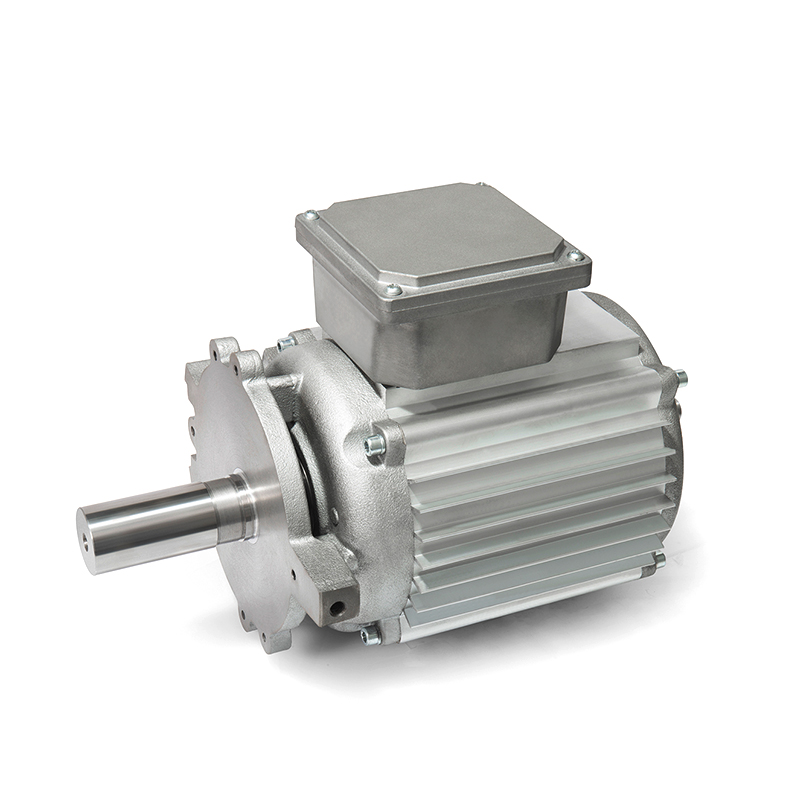

Brushless DC (BLDC) motors have revolutionized industries ranging from robotics and automotive to consumer electronics and aerospace. Known for their high efficiency, reliability, and low maintenance, BLDC motors are increasingly replacing traditional brushed motors in modern applications. However, selecting the right BLDC motor for a specific application requires a careful understanding of performance requirements, environmental conditions, and motor characteristics. This guide explores how to choose the ideal brushless DC motor to meet your technical and operational needs.

Understanding Brushless DC Motors

A brushless DC motor is an electric motor that operates without mechanical brushes, using electronic controllers to deliver current to the motor windings. Unlike brushed motors, BLDC motors eliminate friction and wear associated with brushes, resulting in higher efficiency, longer life, and quieter operation.

Key Advantages of BLDC Motors:

High Efficiency: Reduced energy loss due to the absence of brushes.

Low Maintenance: No brushes to replace or wear out.

Precision Control: Excellent for applications requiring speed and torque control.

Long Lifespan: Reduced mechanical wear extends operational life.

Quiet Operation: Ideal for noise-sensitive environments.

Given these benefits, BLDC motors are used in drones, electric vehicles, HVAC systems, industrial machinery, medical devices, and household appliances. However, choosing the correct motor involves more than just selecting a brushless type—it requires matching the motor’s specifications to your application’s demands.

Step 1: Define Your Application Requirements

The first step in choosing a BLDC motor is to clearly define your application requirements. Consider the following:

Load Characteristics

Determine whether the load is constant or variable.

Understand the torque requirements, including starting torque and peak torque.

Identify any inertia or acceleration demands, especially in robotics or high-speed machinery.

Speed Requirements

Define the operating speed range (RPM) and whether speed must be precisely controlled.

High-speed applications, such as drones or centrifugal pumps, require motors rated for elevated RPMs.

Power Source

Decide whether the motor will be powered by DC voltage from a battery, a regulated DC supply, or other power sources.

Ensure the voltage and current ratings of the motor match the available power supply.

Environmental Conditions

Consider exposure to dust, moisture, temperature extremes, or chemicals.

Certain motors may require sealed enclosures or IP-rated protection for harsh environments.

Control Requirements

Determine if you need simple on/off operation or complex motion control.

Applications requiring precise positioning may benefit from BLDC motors with integrated encoders.

Step 2: Select the Motor Type

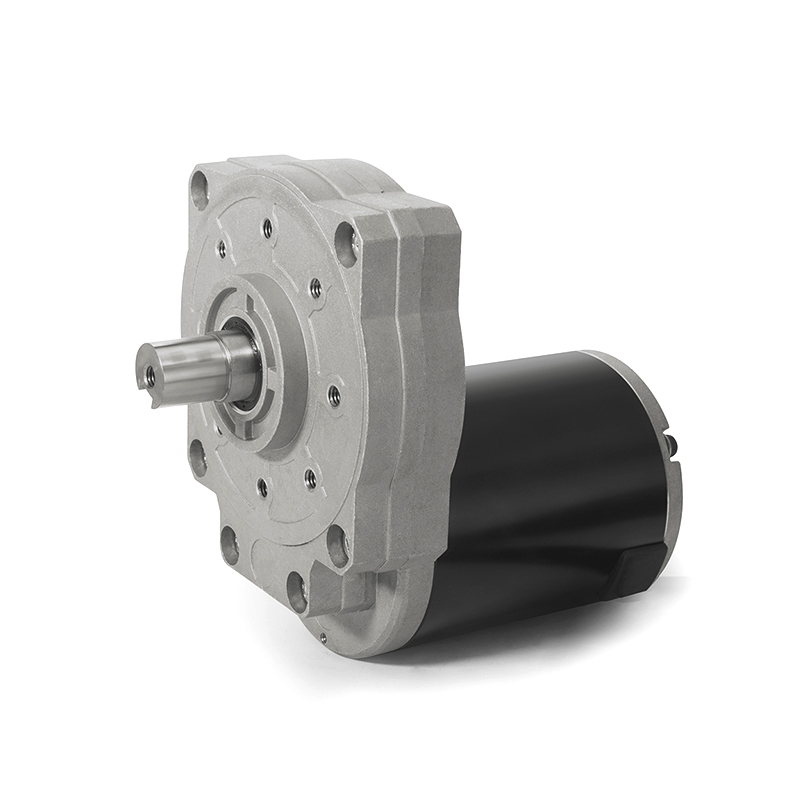

BLDC motors come in various configurations, each with unique features suited to different applications:

Inner Rotor Motors

The rotor is located inside the stator.

Offers high-speed performance and is common in fans, drones, and precision machinery.

Outer Rotor Motors

The rotor surrounds the stator.

Provides high torque at low speeds, ideal for direct-drive applications and robotic arms.

Sensorless vs. Sensored Motors

Sensored BLDC Motors: Include Hall effect sensors or encoders to detect rotor position, allowing precise speed and position control.

Sensorless BLDC Motors: Rely on back EMF for rotor position detection, suitable for simpler applications with less precise control needs.

Coreless and Slotless Motors

Lightweight and low inertia, offering fast acceleration and minimal cogging.

Ideal for high-precision medical devices, drones, or robotics where smooth motion is critical.

Selecting the motor type depends on speed, torque, precision, and size requirements for your application.

Step 3: Determine Key Motor Specifications

Once you know your application and motor type, evaluate the essential specifications:

Voltage and Current Ratings

Match the motor to your power supply to ensure stable operation without overheating.

Higher voltage motors typically allow higher speeds, while higher current provides increased torque.

Torque Characteristics

Identify continuous torque (the torque the motor can sustain without overheating) and peak torque (maximum torque for short durations).

Applications like electric vehicles or industrial machinery may require high peak torque for acceleration or load changes.

Speed Range

Verify that the motor can achieve the desired RPM under load conditions.

Consider gear reduction if torque requirements exceed the motor’s direct output.

Efficiency

High-efficiency motors reduce energy consumption and heat generation.

Efficiency is especially important for battery-powered applications like drones and EVs.

Thermal Management

Ensure the motor can handle operating temperatures and dissipate heat effectively.

Some applications may require forced cooling or heat sinks.

Size and Weight Constraints

Consider available space and weight limitations.

Coreless or slotless BLDC motors are preferred when lightweight compact solutions are necessary.

Noise Levels

Some BLDC motors operate quietly, making them suitable for medical or indoor applications.

Step 4: Evaluate Control Options

BLDC motors require electronic controllers to operate, so selecting the right control method is crucial:

Open-Loop Control (Sensorless)

Simple and cost-effective.

Suitable for applications with steady speed and moderate torque requirements.

Closed-Loop Control (Sensored)

Provides precise speed, torque, and position control.

Required for robotics, CNC machines, and drones where accurate motion is critical.

PWM Control

Pulse Width Modulation (PWM) is commonly used for speed regulation and energy efficiency.

High-frequency PWM reduces noise and improves motor response.

Integrated Controllers

Some BLDC motors come with built-in drivers for easier integration.

Simplifies wiring and reduces system complexity, ideal for consumer electronics.

Step 5: Consider Environmental and Operational Factors

Environmental factors can affect motor performance:

Temperature

Motors generate heat during operation; excessive heat can reduce lifespan.

High-temperature environments may require motors with higher insulation class or forced cooling.

Humidity and Dust

Motors exposed to moisture or dust require sealed housings or IP-rated protection.

Vibration and Shock

Industrial machinery and automotive applications may need robust BLDC motors with reinforced construction.

Duty Cycle

Determine whether the motor will operate continuously or intermittently.

Continuous high-load operation may require enhanced cooling and higher-rated motors.

Step 6: Balance Cost and Performance

While selecting a motor, balance performance requirements with budget constraints:

High-precision, high-torque motors tend to be more expensive.

Sensorless or standard BLDC motors are cost-effective for simpler applications.

Integrated motor-controller solutions may save installation costs but have a higher upfront price.

Investing in a slightly higher-quality motor can reduce downtime, maintenance costs, and improve overall system reliability.

Step 7: Test and Validate

Before committing to mass deployment, it’s crucial to test the selected BLDC motor in real-world conditions:

Verify that the motor meets torque, speed, and efficiency requirements under actual load.

Ensure that thermal performance, noise levels, and vibration are acceptable.

Check compatibility with the controller and power supply.

Prototyping helps avoid costly mistakes and ensures that the motor performs reliably in its intended application.

Conclusion

Choosing the right brushless DC motor involves a careful analysis of your application requirements, motor type, specifications, control methods, environmental factors, and budget. By understanding the characteristics of BLDC motors—such as torque, speed, efficiency, thermal performance, and control options—you can select a motor that maximizes performance, minimizes maintenance, and ensures long-term reliability.

Whether you are designing drones, robotics systems, industrial machinery, electric vehicles, or consumer electronics, selecting the ideal BLDC motor is critical for success. Taking a systematic approach ensures your motor delivers precision, efficiency, and durability, making it a perfect fit for your specific application.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体