What Makes Brushless DC Motors Superior to Traditional Motors?

In today’s fast-moving world of technology and automation, motors are the silent workhorses driving countless applications—ranging from household appliances and electric vehicles to drones and industrial machines. Among all motor types, Brushless DC Motors (BLDC motors) stand out as a revolutionary advancement that has transformed the way we think about efficiency, performance, and durability.

But what makes brushless DC motors so special? Why are they replacing traditional brushed motors in so many industries? Let’s explore their history, working principle, advantages, applications, and future prospects.

What Is a Brushless DC Motor?

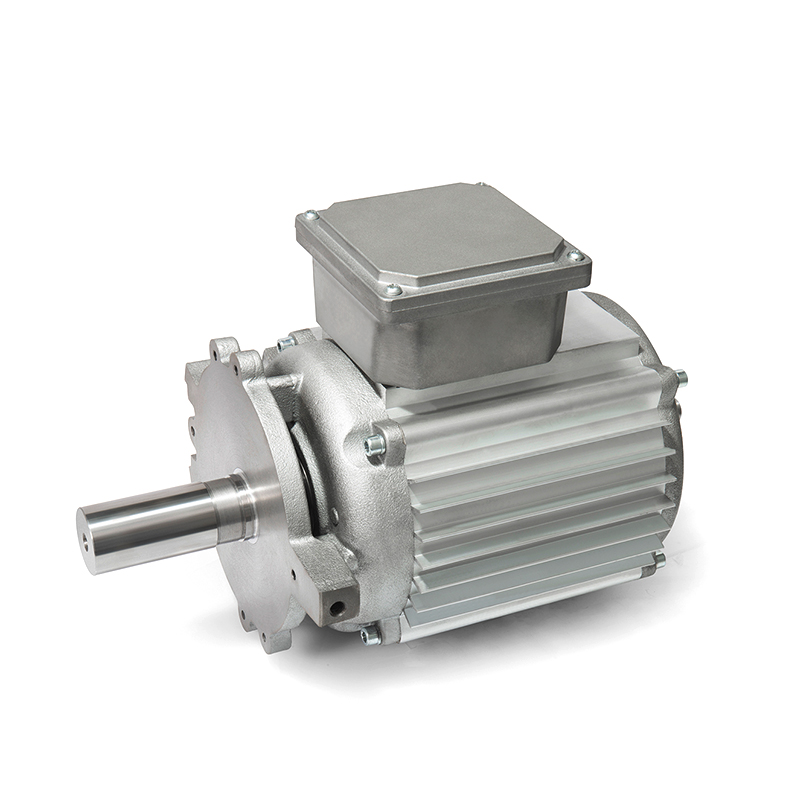

A Brushless DC motor is an electric motor that operates using direct current (DC) but without the mechanical brushes and commutator found in traditional brushed motors. Instead of brushes, it uses an electronic controller to switch current between the motor windings, producing a rotating magnetic field that drives the rotor.

This design makes BLDC motors more reliable, efficient, and longer-lasting than their brushed counterparts, making them the preferred choice in modern engineering.

How Do Brushless DC Motors Work?

The working principle of a BLDC motor is based on the interaction between the stator and rotor magnetic fields:

Stator (Stationary Part): Contains windings powered by DC electricity, controlled electronically to generate a rotating magnetic field.

Rotor (Rotating Part): Typically equipped with permanent magnets. The rotor follows the rotating field generated by the stator.

Electronic Controller: Instead of brushes, a semiconductor-based controller ensures the current switches at the right time, allowing smooth rotation.

This electronic commutation eliminates physical contact between moving parts, which is the core advantage of BLDC technology.

Key Advantages of Brushless DC Motors

1. Higher Efficiency

BLDC motors convert electrical energy into mechanical energy with minimal losses. Efficiencies often exceed 85–90%, making them ideal for applications requiring energy conservation.

2. Longer Lifespan

The absence of brushes means there is less wear and tear. BLDC motors can last tens of thousands of hours with little maintenance.

3. Low Noise and Smooth Operation

Since no brushes are making or breaking electrical contact, BLDC motors operate quietly and smoothly—important for medical devices, home appliances, and electric vehicles.

4. High Power-to-Weight Ratio

BLDC motors are compact but deliver high torque, making them well-suited for drones, robotics, and aerospace applications.

5. Precise Speed Control

With electronic controllers, BLDC motors allow for accurate control of speed and torque, critical in automation, CNC machines, and robotics.

6. Reduced Maintenance

No brushes mean no frequent replacement of worn-out components, saving time and costs.

Brushless vs. Brushed DC Motors

Brushed Motors: Use mechanical brushes to deliver current, causing friction, wear, and noise. They are inexpensive but require more maintenance.

Brushless Motors: Use electronic commutation, offering greater efficiency, reliability, and control at a slightly higher initial cost.

In the long term, the superior durability and efficiency of BLDC motors make them more cost-effective than brushed motors.

Applications of Brushless DC Motors

The versatility of BLDC motors is one of the main reasons they dominate modern industries. Here are some key applications:

1. Electric Vehicles (EVs)

BLDC motors are the heart of many electric cars and bikes, providing high torque, energy efficiency, and smooth acceleration.

2. Drones and UAVs

Lightweight, high-torque BLDC motors allow drones to lift off, maneuver, and hover with stability.

3. Industrial Automation

Used in CNC machines, robotics, and conveyors where precision and reliability are critical.

4. Home Appliances

Washing machines, refrigerators, air conditioners, and vacuum cleaners use BLDC motors for quiet, efficient performance.

5. Medical Equipment

Devices like ventilators, surgical tools, and imaging machines rely on BLDC motors for precise, silent operation.

6. Aerospace and Defense

High-performance drones, satellites, and weapon systems benefit from their efficiency and reliability.

Challenges of Brushless DC Motors

While BLDC motors offer remarkable benefits, they also come with certain challenges:

Higher Initial Cost – Electronic controllers make them more expensive than brushed motors upfront.

Complexity – The need for sophisticated control systems requires more expertise and resources.

Controller Dependency – If the electronic controller fails, the motor cannot function, making reliability of the controller critical.

Despite these challenges, the long-term savings and superior performance outweigh the drawbacks in most applications.

Recent Trends Driving BLDC Motor Adoption

Rise of Electric Vehicles: With EVs becoming mainstream, demand for BLDC motors is skyrocketing.

Energy Efficiency Regulations: Stricter global efficiency standards push industries to adopt BLDC motors.

Smart Home and IoT Devices: Compact, quiet motors are essential for modern household gadgets.

Robotics and Automation: Precision control and reliability make BLDC motors the backbone of Industry 4.0.

Renewable Energy Systems: BLDC motors are increasingly used in wind turbines and solar trackers.

The Future of Brushless DC Motors

The future of BLDC motors looks exceptionally bright, thanks to advancements in electronics, materials, and energy storage. Some emerging directions include:

Integration with AI and IoT: Smart controllers that optimize motor performance in real time.

Miniaturization: Smaller yet more powerful motors for medical implants, micro-drones, and wearables.

Sustainability: Eco-friendly designs using recyclable materials and energy-efficient controllers.

High-Power EV Motors: Development of BLDC motors that deliver even greater torque and efficiency for heavy-duty vehicles.

As industries move toward cleaner, smarter, and more efficient technologies, BLDC motors will remain at the core of innovation.

Conclusion

Brushless DC motors represent a significant leap forward in motor technology. With their unmatched efficiency, durability, and precision, they are revolutionizing industries ranging from automotive and aerospace to consumer electronics and healthcare.

While their initial cost may be higher, the long-term benefits in energy savings, reliability, and maintenance make them the clear choice for the future. As we step into an era defined by sustainability, automation, and smart technology, BLDC motors will continue to power progress—silently, efficiently, and reliably.

-

Feedback

Hotline:0086-15869193920

Time:0:00 - 24:00

English

English Deutsch

Deutsch italiano

italiano 中文简体

中文简体